How to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

George Schuetz

Director of Precision Gages, Mahr Inc.

Bring the Surface Finish Check to the Part

Dedicated handheld gages can assist the operator in making critical checks.

Reading What the Dial Indicator Is Saying

Dial indicators provide good value for their resolution. With a glance, one can quickly determine if the part is larger or smaller than the master setting and by a degree of how much.

Performance Digital Comparators Offer an Alternative to Bench Amplifiers

Electronics today allow for matching the linear variable differential transformer performance and digital indicator size into a new digital comparator that provides even more value than traditional bench amplifiers.

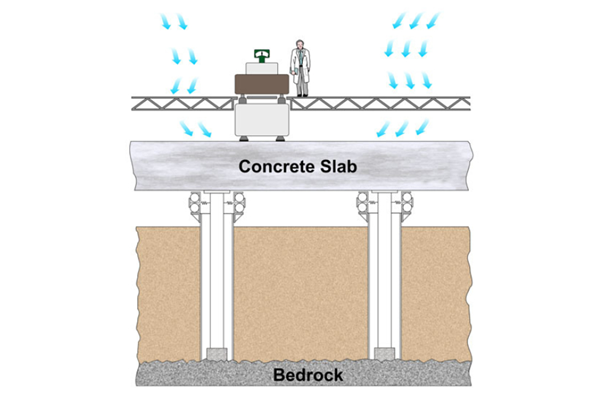

Determining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

Sensitive and Strong: Advanced Digital Comparators

Borrowing from cell phone touchscreen technology, user interfaces on industrial gages are increasingly sensitive — and strong.

How to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.