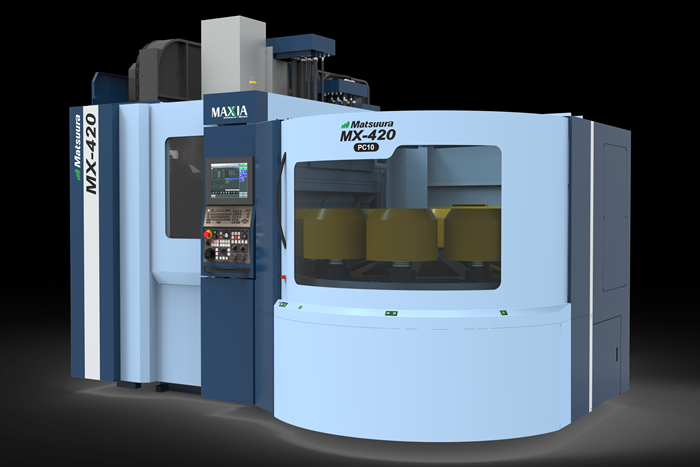

A horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. One reason for this is that the horizontal orientation encourages chips to fall away, so they don’t have to be cleared from the table. More significantly, the horizontal design allows a two-pallet workchanger to be incorporated into a space-efficient machine. To save time, work can be loaded on one pallet of a horizontal machining center while machining occurs on the other pallet.

Starrag's New Compact HMC Increases Speed, Output

The Heckert H65 provides traverse rates up to 80 m/min and a standard spindle speed of up to 10,000 revs/min from its 60 kW/450 Nm hollow shaft HSK-A100 spindle. A motor spindle with a run-up time of one second can be used for machining light alloys.

Horizontal Machining Centers: Essential Reading

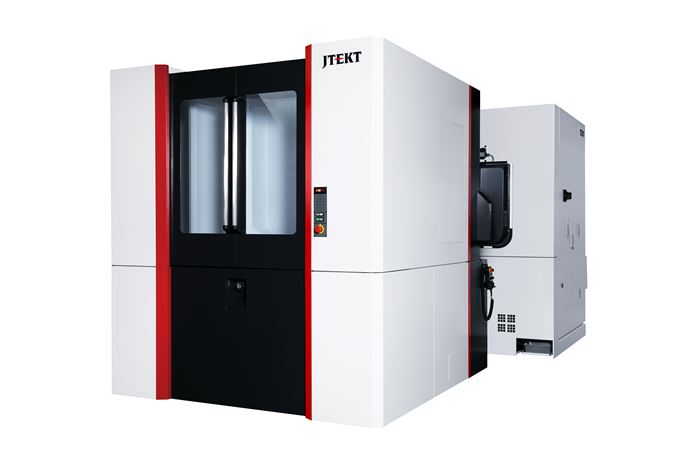

Niigata Launches HMC With Hardened, Ground Inverted V-Shaped Slideways

According to Niigata, the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

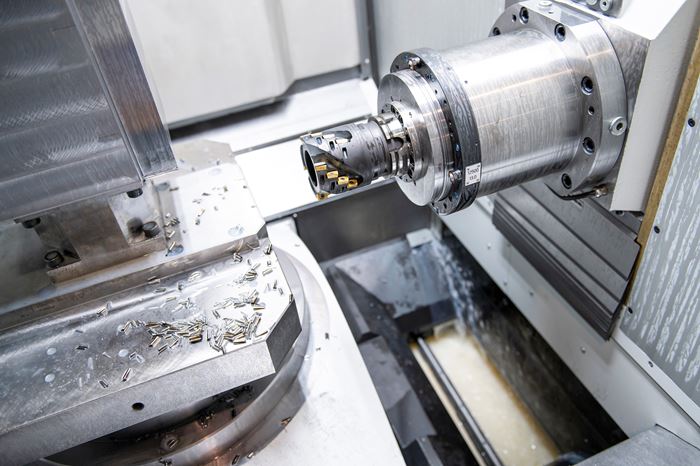

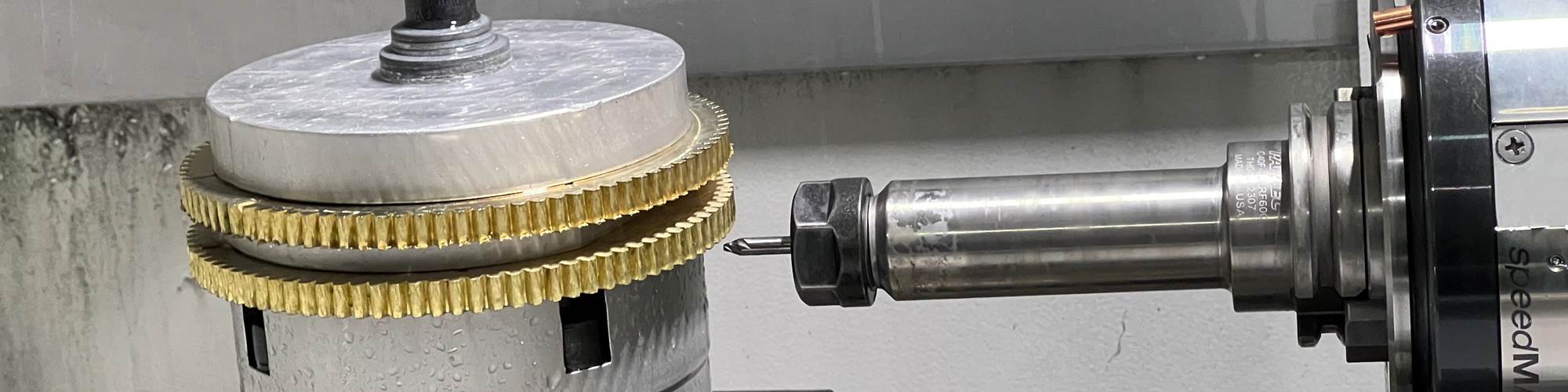

Back to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

Starrag Five-Axis HMC Joins AMRC's Factory of the Future

Starrag Heckert’s X40 joins a series of other multi-axis Starrag-supplied machines at the University of Sheffield Advanced Manufacturing Research Centre’s Factory of the Future.

Mazak Upgrades Vertical and Horizontal Machining Centers

According to Mazak, both the HCN-6800 NEO and the Variaxis i-800 NEO include a fully redesigned enclosure and improvements that enable fast, optimal solutions for a wide range of part-production applications.

Niigata Introduces High-Speed Jig Borer Machining Center

Niigata says the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

FAQ: Horizontal Machining Centers

What is a horizontal machining center?

Horizontal and vertical three-axis machines differ primarily in the inclination of the spindle, with the spindles of horizontal machines parallel to the surface of the machine table and the spindles of vertical machines perpendicular to the surface, although individual constructions vary widely to support different applications.

What is a machining center?

Typically, machining centers are numerically controlled machines with multipurpose capabilities. This flexibility not only allows for productivity improvements but also allows for one machine to replace several single-purpose machines.

Machining centers provide the ability to perform several operations on a workpiece, from roughing to finishing, with a single setup.

Why should you buy a horizontal machining center?

The simple answer is productivity and profit. Horizontals can easily do three times the work of a comparable VMC. This assertion assumes that the workload to keep the machine busy is available. Without question, you can get more done in far less time using an HMC. With the increase in production, shop throughput is greatly improved. Because multiple operations can be done in a single setup on an HMC, less work in process must move around the shop, increasing efficiency.

Source: Buying an HMC: What Makes Horizontal Machining Centers Different

What are some additional costs of adding a horizontal machining center?

To make full use of the higher-level machine, other parts of the process need to be raised to a higher level as well. Here is a partial list of the additional investments to be made:

1. Inspection equipment.

2. Computers.

3. Coolant.

4. Tool presetter.

5. Fixturing.

6. Tool vending.

Horizontal Machining Centers Suppliers

Narrow by Horizontal Machining Centers Category

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Horizontal Machining Center From Okuma Offers New Features

The new machining center offers a larger work envelope, enhanced chip and coolant management functions and automation compatibility, among other features.

Starrag's New Compact HMC Increases Speed, Output

The Heckert H65 provides traverse rates up to 80 m/min and a standard spindle speed of up to 10,000 revs/min from its 60 kW/450 Nm hollow shaft HSK-A100 spindle. A motor spindle with a run-up time of one second can be used for machining light alloys.

Niigata Launches HMC With Hardened, Ground Inverted V-Shaped Slideways

According to Niigata, the HN800-V is built with the rigidity and accuracy necessary to perform ultra-precise contour machining and boring of components with critical tolerances.

Back to the Charts for Productive Milling

Roughing operations can push a CNC spindle to its limits. Understanding how to interpret the horsepower chart can keep these operations within safe limits.

Starrag Five-Axis HMC Joins AMRC's Factory of the Future

Starrag Heckert’s X40 joins a series of other multi-axis Starrag-supplied machines at the University of Sheffield Advanced Manufacturing Research Centre’s Factory of the Future.

Mazak Upgrades Vertical and Horizontal Machining Centers

According to Mazak, both the HCN-6800 NEO and the Variaxis i-800 NEO include a fully redesigned enclosure and improvements that enable fast, optimal solutions for a wide range of part-production applications.