Mazak Upgrades Vertical and Horizontal Machining Centers

According to Mazak, both the HCN-6800 NEO and the Variaxis i-800 NEO include a fully redesigned enclosure and improvements that enable fast, optimal solutions for a wide range of part-production applications.

Mazak is introducing upgraded versions of its HCN series of horizontal machining centers and Variaxis series of vertical machining centers, including the HCN-6800 NEO and the Variaxis i-800 NEO. According to Mazak, each includes a fully redesigned enclosure and improvements that enable fast, optimal solutions for a wide range of part-production applications.

The HCN-6800 NEO features an upgraded spindle, table and magazine, a standard 43-tool drum-type magazine that reportedly reduces tool exchange times. For ease of maintenance, the machine incorporates hydraulic/motorized pallet changer mechanisms and an easier-to-access maintenance panel. In addition, a faster servo-driven ATC door design now also accommodates longer tools. Mazak also offers a direct drive motor table that the company claims will ensure fast indexing time and rotary scales for high-accuracy positioning.

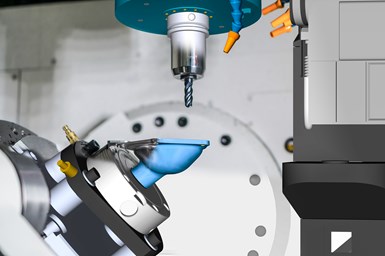

Mazak’s Variaxis i-800 NEO five-axis machine features faster rapid traverse rates for shorter machining cycle times, expanded workpiece capacities and more automation options. Automation options include a two-pallet changer, along with the Mazak Multi-Pallet Pool (MPP) compact multiple pallet stocker system and themodular Mazak Palletech System.

Both the Variaxis i-800 NEO, equipped with the Mazatrol SmoothAi CNC, and the HCN-6800 NEO with the Mazatrol SmoothG CNC, incorporate Mazak’s Thermal Shield functionality. Mazak claims this system compensates instantly for changes in machine and ambient temperature during operation, ensuring the highest degree of accuracy even over long machining cycles.

Mazak will showcase these machines and more at its Discover event from October 25-29, 2021 in Florence, Ky.

RELATED CONTENT

-

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

-

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

-

Rolling Threads Has Advantages

With macros and canned cycles resident in the CNC on most contemporary turning centers, single point turning of OD threads can seem like almost a default process decision. However, for numerous applications, OD thread rolling has inherent advantages as an alternative to cutting threads.

%20(1).1676494398075.png)