Deburring is perhaps the most critical post-machining operation for ensuring the functionality of the machined part, as well as the safe handling of the part. Deburring has traditionally been a task that takes place after machining to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

April 2019 Product Spotlight: Cleaning and Deburring

This month’s Modern Equipment Review Spotlight focuses on equipment used to remove imperfections from and clean finished workpieces.

Deburring: Essential Reading

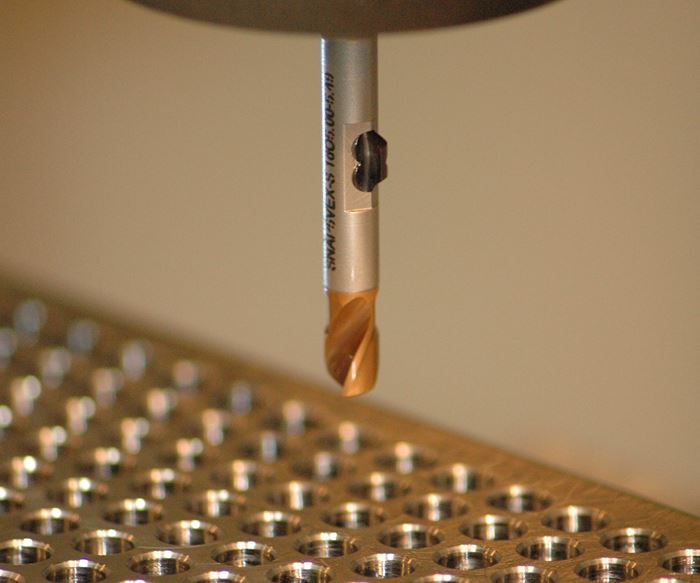

Carbide Burrs Make Smaller, Granular Chip Breaks

Designed for surface removal on demanding production runs, Saint-Gobain Abrasives’ line of Norton double-cut carbide burrs is said to last longer with fewer change-overs on challenging production applications.

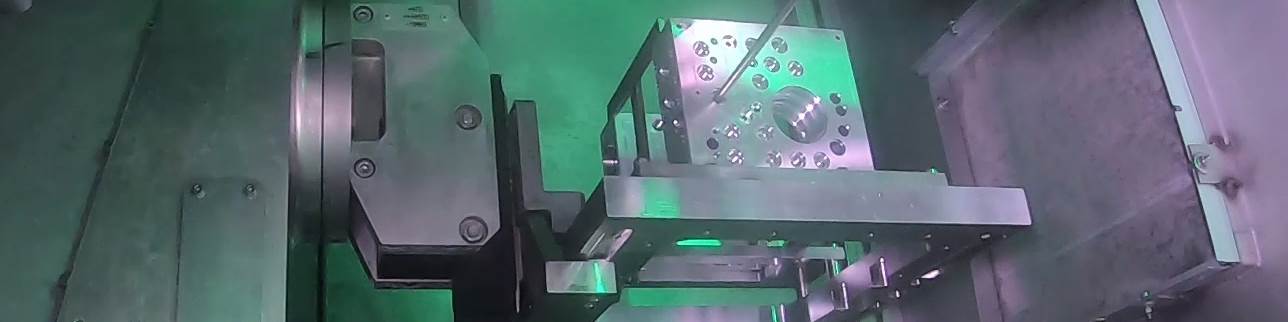

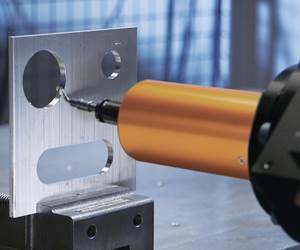

Tool Speeds Cross-Bore Deburring

IMTS 2018: Heule Tool’s COFA deburring tool is designed to provide front and back deburring on even and uneven surfaces.

Back-Spotfacing Tool Frees Production from Costly Bottlenecks

By removing the need to detach and reattach the cutting head in a traditional back-spotfacing process, a cutting tool from Heule saved Sicom Industries two to three hours per part.

Deburring Tools Come in Four Application-Specific Versions

Heule Tool’s X-Bore tooling for the automated deburring of cross bores is available in four chipmaking tool versions to address four different challenges of deburring: Cofa, Cofa-X, Main Bore Tool and Cross Bore Deburring Tool.

Rotary Vibrator Suitable for Orthopedic Implant Finishing

Rosler’s R 150 DL-2 rotary vibrator is designed to avoid part-on-part contact for processing orthopedic implants, achieved by mounting workpieces to a fixture inside of the work bowl.

FAQ: Deburring

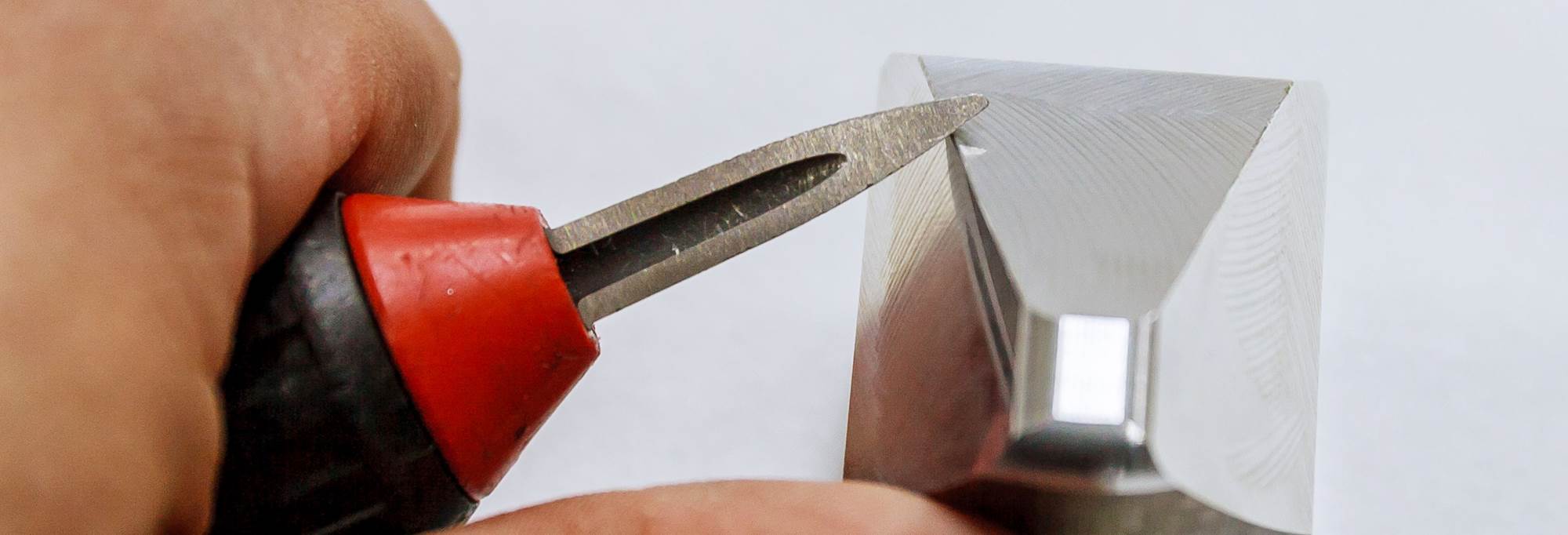

What is deburring?

Deburring has traditionally been a manual task that takes place after machining to remove any remaining sharp pieces of metal.

What is a deburring tool used for?

A deburring tool is used to remove any remaining sharp pieces of metal necessary to achieve the desired finish. Deburring has traditionally been a manual task, but various technologies exist for reliably automating deburring.

Deburring Suppliers

Narrow by Deburring Category

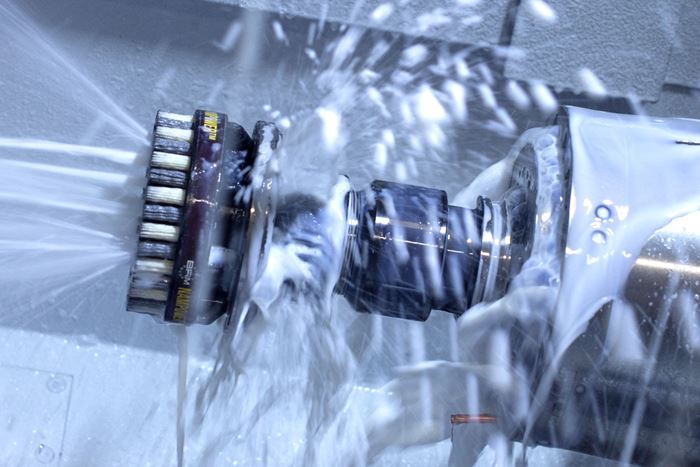

Automated Part Deburring, Cleaning in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

#Basics #partscleaning

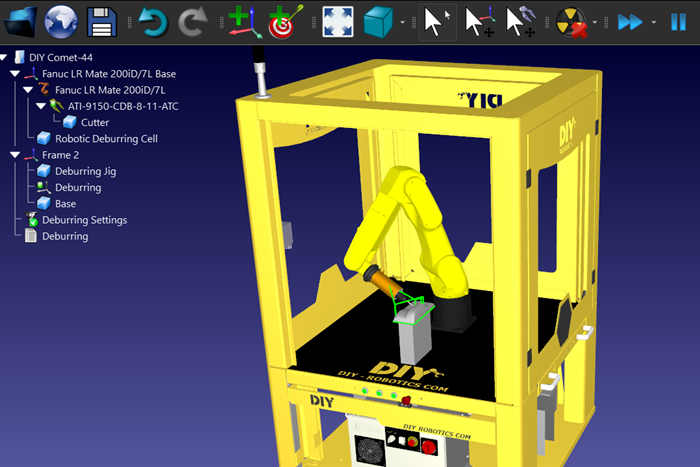

ATI Offers Deburring Blade Suitable for Automation

The pneumatically controlled, articulated design of ATI Industrial Automation’s Compliant Deburring Blade (CDB) enables users to tune the contact force to accommodate specific applications by changing the air pressure.

April 2019 Product Spotlight: Cleaning and Deburring

This month’s Modern Equipment Review Spotlight focuses on equipment used to remove imperfections from and clean finished workpieces.

#partscleaning

Carbide Burrs Make Smaller, Granular Chip Breaks

Designed for surface removal on demanding production runs, Saint-Gobain Abrasives’ line of Norton double-cut carbide burrs is said to last longer with fewer change-overs on challenging production applications.

Tool Speeds Cross-Bore Deburring

IMTS 2018: Heule Tool’s COFA deburring tool is designed to provide front and back deburring on even and uneven surfaces.

#imts

Back-Spotfacing Tool Frees Production from Costly Bottlenecks

By removing the need to detach and reattach the cutting head in a traditional back-spotfacing process, a cutting tool from Heule saved Sicom Industries two to three hours per part.

#casestudy

Deburring Tools Come in Four Application-Specific Versions

Heule Tool’s X-Bore tooling for the automated deburring of cross bores is available in four chipmaking tool versions to address four different challenges of deburring: Cofa, Cofa-X, Main Bore Tool and Cross Bore Deburring Tool.

#Basics