Robotics Partners Design Easy-to-Use Robotic Deburring Cell

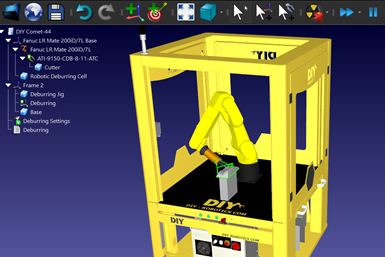

RoboDK, DIY-Robotics and ATI Industrial Automation have released a plug-and-play Robotic Deburring Cell technology bundle, which they say rapidly integrates into user systems.

Robot software company RoboDK has partnered with DIY-Robotics and ATI Industrial Automation to release a combined application bundle for robotic deburring. The companies say they chose deburring as the task is dull for humans to perform and benefits from the increased consistency that robots provide. Their new plug-and-play robotic deburring cell provides a self-contained system for this task, and is deployable within days.

The solution is based around DIY-Robotics’ pre-engineered robotic cell, to which ATI Industrial Automation provides its compliant deburring tool. This tool accounts for variations in part and feature location through its compliant tip and can complete a wide range of deburring tasks.

"Robotics can appear complex to handle when it comes to coding languages and the complexity behind the technology," says Steve Blanchette, president of DIY-Robotics. "The main advantage of the Robotic Deburring Cell is its plug-and-play aspect. This bundle allows anyone, regardless of their robotics knowledge, to equip their factory with the latest industrial robotics technology."

DIY-Robotics simplifies the sourcing process by listing its solutions’ prices on its website. The robot cell ships within three weeks of ordering, and is deployable within a few days for turnkey solutions — or can be assembled by the user.

RoboDK provides an offline programming functionality that allows users to create and update programs through a graphical interface, even without prior experience. The company’s optimization tools for robot machining and deburring further assist users in creating error-free programs.

"DIY-Robotics' deburring cell and the ATI's compliant deburring blade are now completely supported by the software,” says Albert Nubiola, RoboDK CEO. “This is a great addition to RoboDK, as it allows users to build a cell for deburring in just a few clicks."

The robotic deburring cell is the first in a series of application-specific, plug-and-play bundles the companies plan to develop.

RELATED CONTENT

-

Rigid Tapping--Sometimes You Need A Little Float

One of the most common methods of tapping in use today on CNC machines is 'rigid tapping' or 'synchronous feed tapping.' A rigid tapping cycle synchronizes the machine spindle rotation and feed to match a specific thread pitch. Since the feed into the hole is synchronized, in theory a solid holder without any tension-compression can be used.

-

Inserts For Difficult Materials

Economic efficiency is an important consideration when choosing tools for challenging metals.

-

A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

(1).1676494398075.png)