CAD/CAM Software is used to generate part designs and CNC machining programs corresponding to part designs. Short for “computer-aided design/computer-aided manufacturing,” these systems create these programs for CNC machine tools. In general, CAM development has proceeded along two different tracks. Geometry-based CAM systems used in die/mold machining and other applications focus on complex milled geometries. Algorithms provide specific and efficient ways for machining complex geometries with both high precision and long tool life. By contrast, feature-based CAM systems are generally used in the production machining of geometrically simpler components.

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

CAD/CAM: Essential Reading

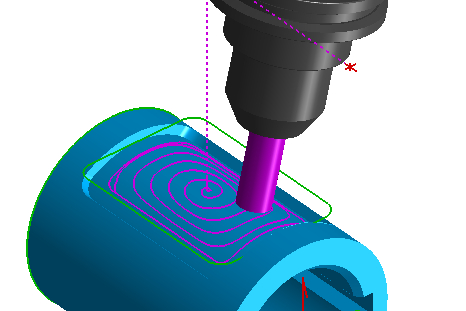

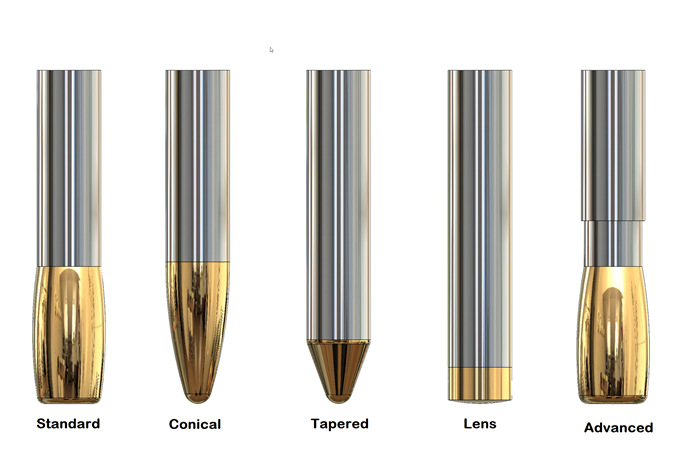

GibbsCAM Update Integrates Turning Enhancements From Sandvik Coromant

GibbsCAM 2023 integrates Sandvik Coromant’s PrimeTurning, which uses the slope of the insert for chip thinning to make heavy cuts and spread cutting forces and heat over a larger portion of the cutting edge.

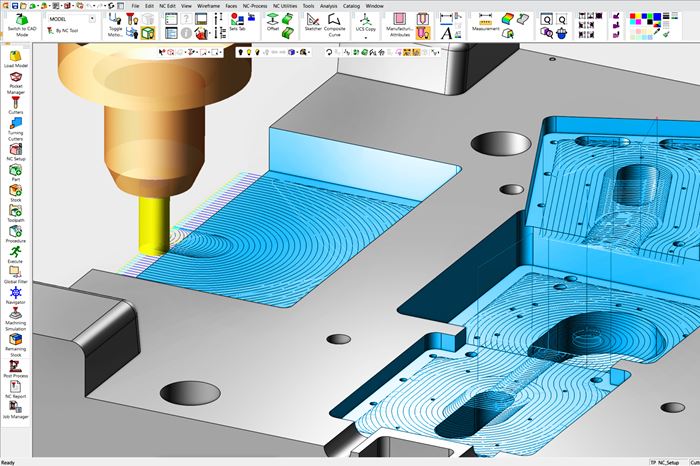

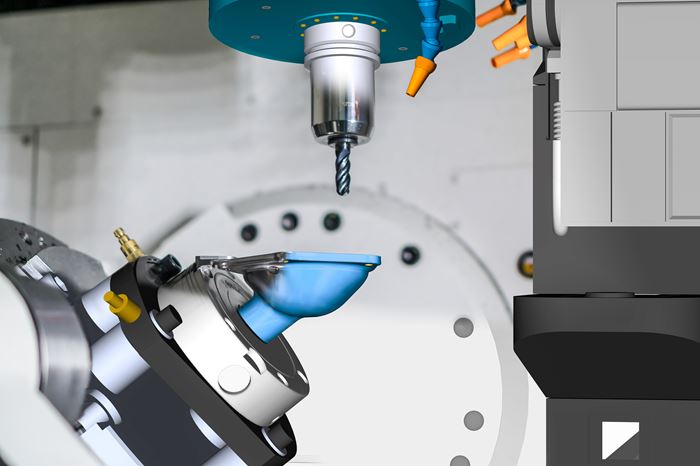

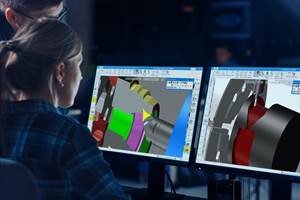

Mastercam Mill Streamlines Multiaxis Machining Process

The Mastercam Mill software package includes multiaxis features, 3D enhancements and 2D high-speed toolpaths.

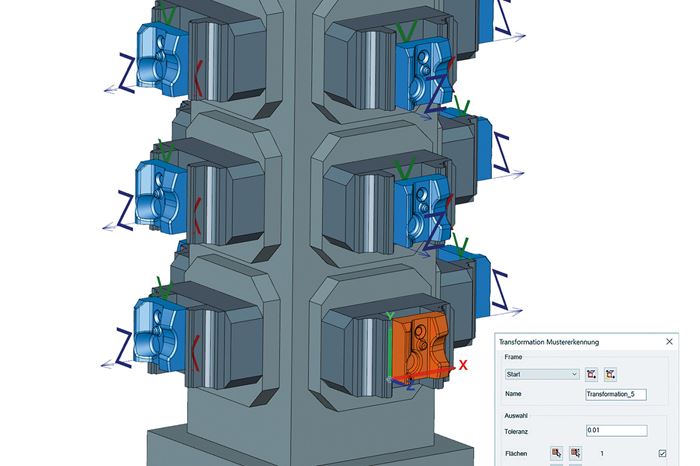

Integrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

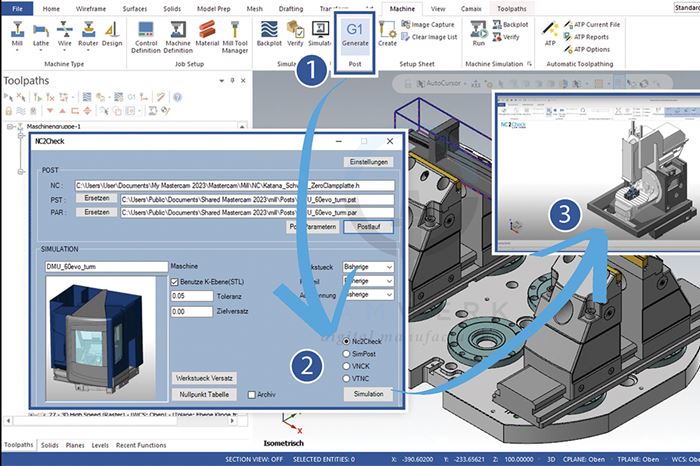

IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and post processing technology to provide a G-code parsing solution that connects directly to Mastercam.

Paperless Parts' Updated 3D Part Viewer Drives Collaboration

The 3D Part Viewer improves manufacturers’ ability to quote faster and more consistently by extracting the geometry of the parts they’re quoting, highlighting manufacturability challenges and enabling collaboration with stakeholders.

FAQ: CAD/CAM

What is CAD/CAM?

In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for programming CNC machine tools. CAD is the computer-aided process that creates a design of a part or object.

Source: CAM at a Crossroads

What is CAD/CAM programming?

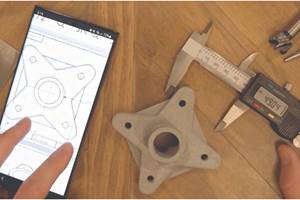

There are three methods of writing CNC programs, including using CAD/CAM software. CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

By using an existing CAD drawing file and importing data into the CAM software, the programmer only needs to decide on which process and tooling to employ, typically using a list of tooling data and cutting conditions. The CAM software then calculates all of the moves necessary to machine the part.

What are the disadvantages of using CAD/CAM?

Programmers must keep in mind that there is some potential for unintentionally entering incorrect data. Another problem is that sometimes, the original drawing file is not available to the CNC programmer.

What is the relationship between CAD and CAM?

Most product design is performed on computers using CAD software. Then, that design or drawing file data is imported into the CAM software. After a few selections from the programmer, the CAM software will use that data and calculate the necessary moves to machine the part.

What are the advantages of CAD/CAM?

CAD/CAM programming minimizes the need for the programmer to perform complex math calculations. Due to the minimal amount of math required by the programmer, CAD/CAM programming tends to be more efficient than manual programming.

CAD/CAM Suppliers

Narrow by CAD/CAM Category

No Such Thing as Luck: A One-Person Shop Owner’s Success Story

You could say he’s a lucky Guy. He has the ideal setup for a moonlighting at-home-machinist: The perfect location, the perfect day job, and a double-threat skill set that allows him to hire himself for prototyping and low-volume production work. But Guy Driscoll’s biggest talent might be creating his own luck.

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

#successionplanning #workforcedevelopment

GibbsCAM Update Integrates Turning Enhancements From Sandvik Coromant

GibbsCAM 2023 integrates Sandvik Coromant’s PrimeTurning, which uses the slope of the insert for chip thinning to make heavy cuts and spread cutting forces and heat over a larger portion of the cutting edge.

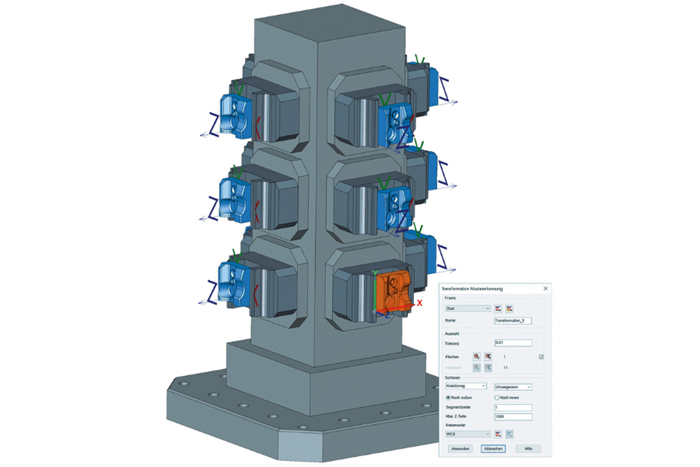

Mastercam Mill Streamlines Multiaxis Machining Process

The Mastercam Mill software package includes multiaxis features, 3D enhancements and 2D high-speed toolpaths.

Integrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and post processing technology to provide a G-code parsing solution that connects directly to Mastercam.

Paperless Parts' Updated 3D Part Viewer Drives Collaboration

The 3D Part Viewer improves manufacturers’ ability to quote faster and more consistently by extracting the geometry of the parts they’re quoting, highlighting manufacturability challenges and enabling collaboration with stakeholders.