Paperless Parts' Updated 3D Part Viewer Drives Collaboration

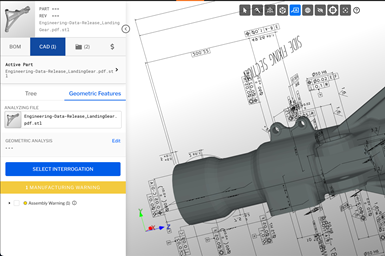

The 3D Part Viewer improves manufacturers’ ability to quote faster and more consistently by extracting the geometry of the parts they’re quoting, highlighting manufacturability challenges and enabling collaboration with stakeholders.

Paperless Parts, a leading estimating and quoting software for job shops and contract manufacturers, announce enhancements to its 3D Part Viewer, a cloud-based, format-agnostic CAD file viewer.

The 3D Part Viewer is said to improve manufacturers’ ability to quote faster and more consistently by extracting the geometry of the parts they’re quoting, highlighting manufacturability challenges and, through Paperless Chat, driving collaboration with internal and external stakeholders, such as machinists, tool providers, raw material suppliers and finishers. Unlike with other viewing tools, Paperless Parts subscribers can invite all stakeholders to view, search and comment on both 2D files (PDF, DXF, emails, videos, Microsoft files and more) and 3D files (all forms of CAD), eliminating the need for collaborators to purchase expensive CAD software licenses or maintain a vast array of format-specific viewers.

Jason Ray, co-founder and CEO of Paperless Parts, says, “A lot of the inefficiency in manufacturing is caused by information asymmetry — designers are designing in 3D, their vendors are quoting based off of 2D PDF files and notes and third-party suppliers are offering input via email. Putting together a holistic picture of a part from design to build is overwhelmingly manual, time consuming and the different stakeholders aren’t able to look at technical data in the same way, which leads to compounding errors and inefficiency.”

By sharing files via Paperless Parts, customers can eliminate the need for expensive file transfer protocol (FTP) point solutions and collaborate within their shop and with vendors, all in a secure environment with the ability to control access when sharing is no longer needed. This functionality is critical to protecting customer data and helps shops serving the defense and aerospace industries comply with International Traffic in Arms Regulations (ITAR) and Cybersecurity Maturity Model Certification (CMMC). The Paperless Parts Viewer also helps customers quickly identify manufacturability warnings such as tight corners, deep holes that require special tooling and bend reliefs.

One of the latest feature enhancements to the Paperless Parts Viewer includes product manufacturing information (PMI) on model-based definition files (MBD) in the Part Viewer. To date, accessing PMI has required additional subscriptions to CAD software, putting this critical information effectively behind a paywall. With Paperless Parts, users can now extract and display PMI — dimensions, tolerances, parallelisms, datums, text annotations — directly in their browser. Data is available from all files that can contain PMI, including STEP AP242, JT files, 3D PDFs, and native formats from platforms like SolidWorks, Catia, PTC Creo and Siemens NX.

Individual face colors are used by designers to annotate features or manufacturing requirements and can have a meaningful impact on the cost to produce a part. For example, individual faces can be colored to indicate surfaces that must be masked when applying a finish, powder coat or faces that need to be cut with a specific operation, such as calling out features that require wire EDM versus a CNC mill. Viewing face colors in the Viewer enables estimators to quickly identify these nuances and price their quotes accordingly.

The Viewer also offers support for etching. While Paperless Parts has identified etched surfaces in the past, new functionality collects them into a separate feature class in the geometric features panel of the Viewer. This grouping enables estimators to quickly view and interact with these etchings versus sifting through sets of features to find them.

Additionally, Paperless Parts’ proprietary file interrogation method, which identifies design for manufacturability warnings and extracts critical dimensions and attributes used to drive automation in the quoting process, is now on average 25% faster. This change impacts both milling and lathe interrogation times, as well as provides users quicker time to first render of the part.

RELATED CONTENT

-

Paperless Parts Quoting Platform Streamlines Estimating Process

Eastec 2023: Recent updates to Paperless Parts include performance enhancements to the 3D Part Viewer that improve the ability to navigate complex parts and assemblies.

-

Hypertherm Associates Adds CAD/CAM Plugin to Robotmaster

The plugin converts Mastercam CAD/CAM data into an optimized robotic program.

-

Cimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

(1).1676494398075.png)