“Turning” defines the work that is traditionally done on a lathe. “Turning centers” is a term sometimes applied to machines with secondary spindles and/or rotating tools for milling and drilling. Another term, “turn/mill or multitasking” describes machines that can be thought of as being just as capable at milling and drilling as they are at turning. Lathes, turning centers and turn-mill machines can have horizontal or vertical spindles, with horizontal being most common. Machines with a vertical spindle are generally called a vertical turret lathe, or VTL. If the workpiece is held from above by the vertical spindle, then this type of turning machine is generally called an inverted vertical lathe.

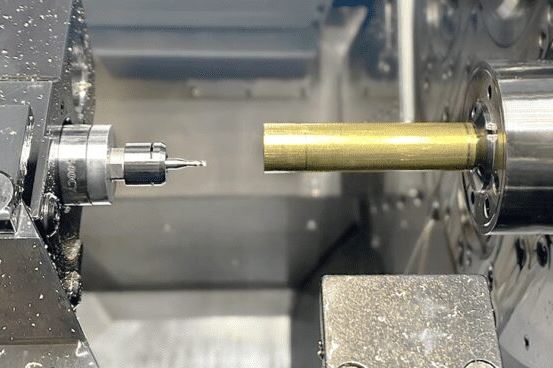

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Turning Machines: Essential Reading

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Tool Lineup Offers Lathes, Mills and More

Kaast Machine Tools highlights up its diverse range of machine tools, fitting customer needs across a variety of applications. The company offers lathes, mills, grinders, presses and more.

EMAG 4-Axes Lathes Deliver Optimized Performance

The lathes are said to provide short cycle times, high-precision machining and safe processing with the VT series of turning machines literally turning the classic horizontal machining process on its head.

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Marubeni Citizen-Cincom Offers Twin-Turret Lathes for Flexible Tooling

Miyano machines are designed to ensure high rigidity, high accuracy and long life.

FAQ: Turning Machines

What is turning?

Turning is the process of using lathes to remove material from the outer diameter of a rotating workpiece. Single-point tools shear metal from the workpiece in (ideally) short, distinct, easily recyclable chips.

Source: Machining 101: What is Turning?

What is a lathe?

One of the key characteristics of a lathe, unlike a vertical or horizontal milling machine, is that the workpiece turns, as opposed to the tool. Thus, lathe work is often called turning. Turning, then, is a machining process used to make round, cylindrical parts.

Source: Buying a Lathe: The Basics

What is the basic configuration of a lathe?

The basic two-axis lathe consists of a headstock with spindle, chuck for holding the part, lathe bed, carriage and cross-slide, tool turret and tailstock. While most lathes have a moveable tailstock to support the workpiece at the end, away from the chuck, not all machines come with this feature as a standard. A tailstock is particularly useful, however, when the workpiece is relatively long and slender.

Source: Buying a Lathe: The Basics

What kinds of spindles do lathes typically have?

The spindle on a turning center is either belt-driven or direct-drive. Generally, belt-driven spindles represent older technology. They speed up and slow down at a lower rate than direct-drive spindles, which means cycle times can be longer. If you’re turning small-diameter parts, the time it takes to ramp the spindle from 0 to 6,000 rpm is significant. In fact, it might take twice as long to reach this speed than with a direct-drive spindle.

What are the types of programmable tailstocks?

A built-in, numerically controlled tailstock can be a valuable feature for automated processes. A fully programmable tailstock provides more rigidity and thermal stability. However, the tailstock casting adds weight to the machine.

There are two basic types of programmable tailstocks—servo-driven and hydraulic. Servo-driven tailstocks are convenient, but the weight they can hold may be limited. Typically, a hydraulic tailstock has a retractable quill with a 6-inch stroke. The quill also can be extended to support a heavy workpiece, and do so with more force than a servo-driven tailstock can apply.

What are some variations of the basic lathe configuration?

Slant-bed lathes provide a number of advantages, while multitasking lathe configurations might open up possibilities heretofore unthought of.

The slant-bed lathe design is probably the most common and well-known configuration in today’s CNC lathes. Typically, the bed of the lathe slants at a 30- or 45-degree angle, although some 60-degree models also are available.

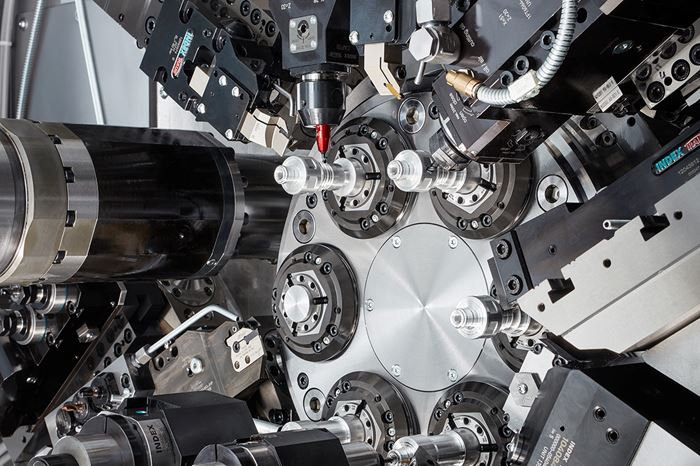

Multitasking machines are often built on a turning center platform. These machines use rotary tools to combine several cutting processes such as turning, milling, drilling, tapping, grooving, threading and deep-hole boring on one machine.

Source: Buying a Lathe: Slant-Beds and Multitasking Configurations

Turning Machines Suppliers

Narrow by Turning Machines Category

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAM system. Here’s how the company succeeded, despite the newness of it all.

#Basics

Expand Machinery Swiss-Type Machine Offers 33 Tool Positions

Expand Machinery’s Genturn-52CS Y2 features a subspindle as well as dual C and Y axes to enable multiple operations in a single handling.

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Tool Lineup Offers Lathes, Mills and More

Kaast Machine Tools highlights up its diverse range of machine tools, fitting customer needs across a variety of applications. The company offers lathes, mills, grinders, presses and more.

EMAG 4-Axes Lathes Deliver Optimized Performance

The lathes are said to provide short cycle times, high-precision machining and safe processing with the VT series of turning machines literally turning the classic horizontal machining process on its head.

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

#Basics

Marubeni Citizen-Cincom Offers Twin-Turret Lathes for Flexible Tooling

Miyano machines are designed to ensure high rigidity, high accuracy and long life.