Workholding refers to any device that is used to a secure a workpiece against the forces of machining. The most basic workholding device is a simple clamp, but workholding can also involve complex fixtures that are custom-built for particular parts. Other common workholding devices include vises and chucks, as well as indexers or rotary tables that are able to change the part’s position while it is held, so the machine can reach various features. In most machining applications, workholding also locates the part. On a machining center, for example, a vise or fixture may also provide the precise position and orientation where the machining program expects to find the workpiece.

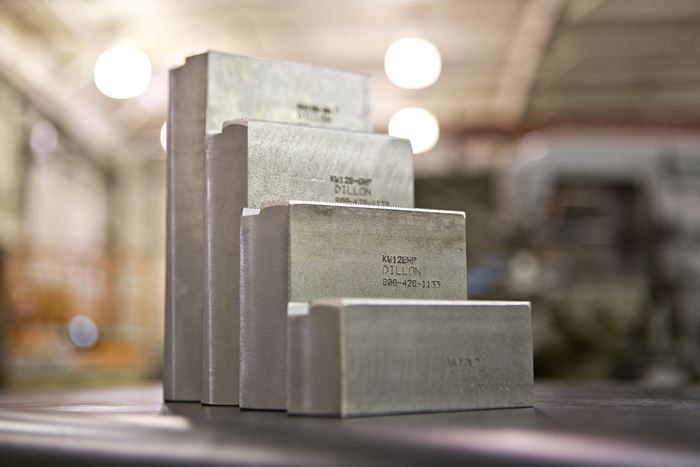

Dillon Soft Jaw Blanks Feature Milled Surface

Dillon jaw sets reduce set-up times, aid concentric performance, provide better chuck balance and enable longer jaw life because of the increased jaw accuracies.

Workholding: Essential Reading

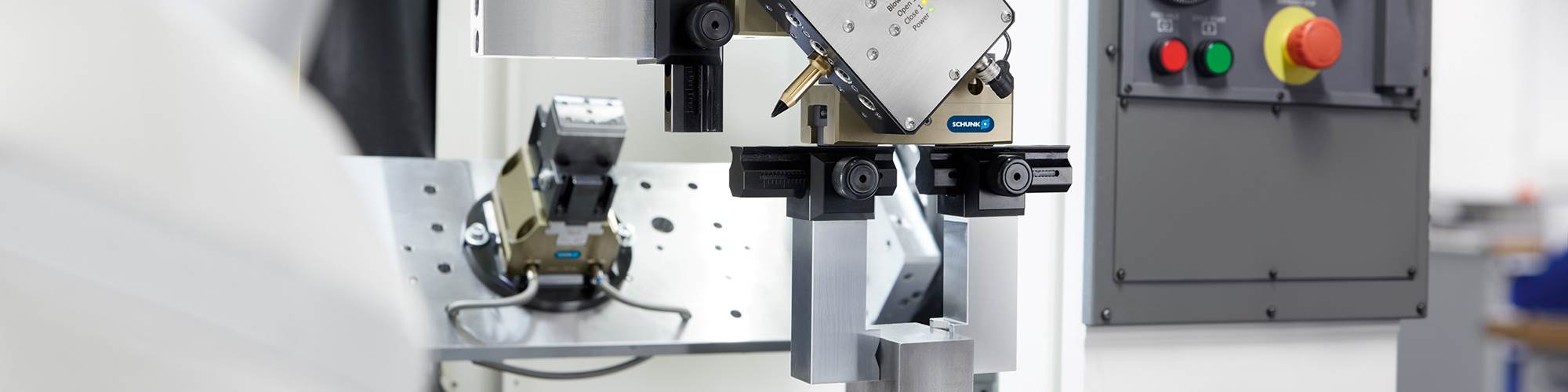

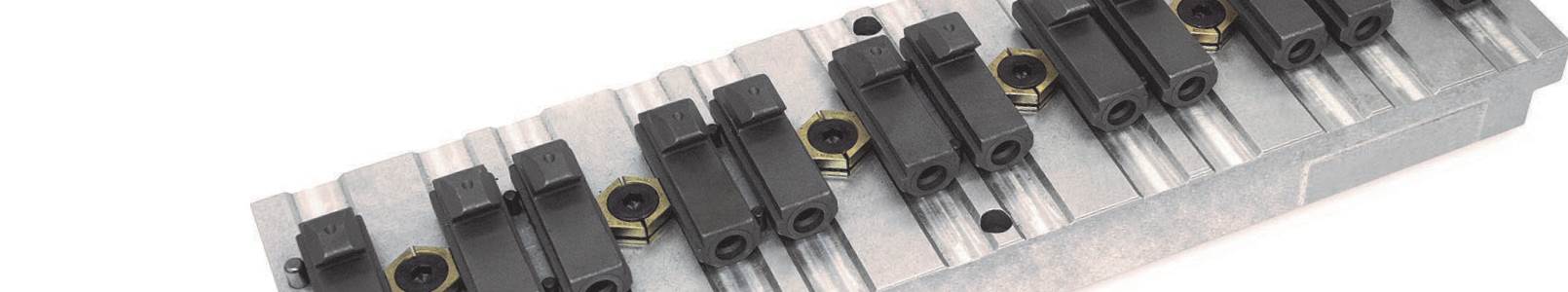

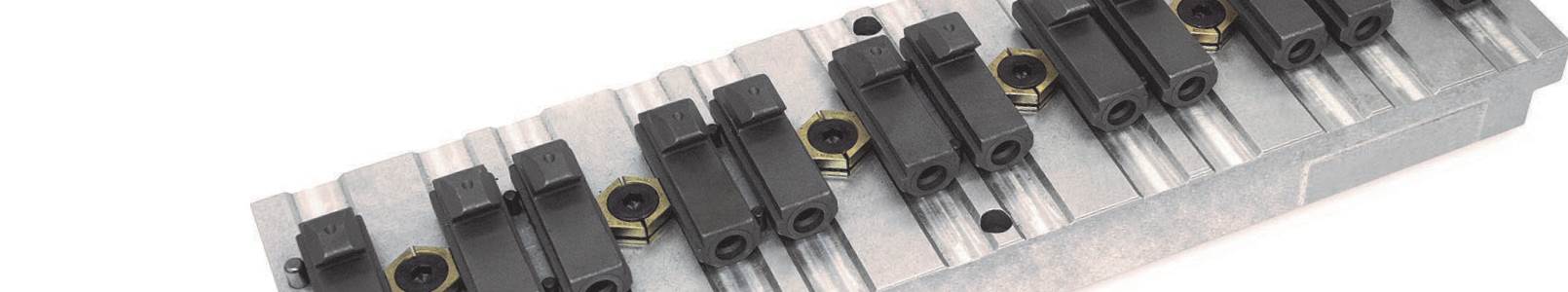

SMW Autoblok Introduces Custom Setup Stations for Machine Tools

The company’s custom setup stations offer complete interchangeability across all machines with a common interface.

Jergens Inc. Introduces Cast Iron Tooling Columns

The cast iron tooling columns are said to increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs.

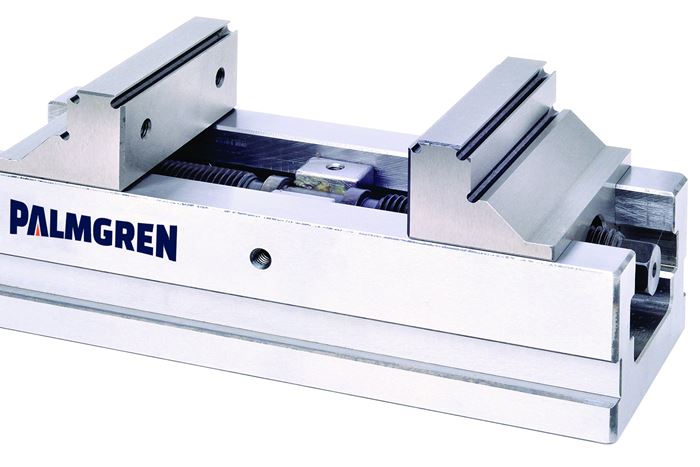

Palmgren Vises Enable Five-Sided Access to Workpieces

Palmgren’s Five-Axis Machine Vises are equipped with self-centering jaws that reduce clamping time and provide a workholding solution for a variety of workpieces, including square, round or odd-shaped parts.

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

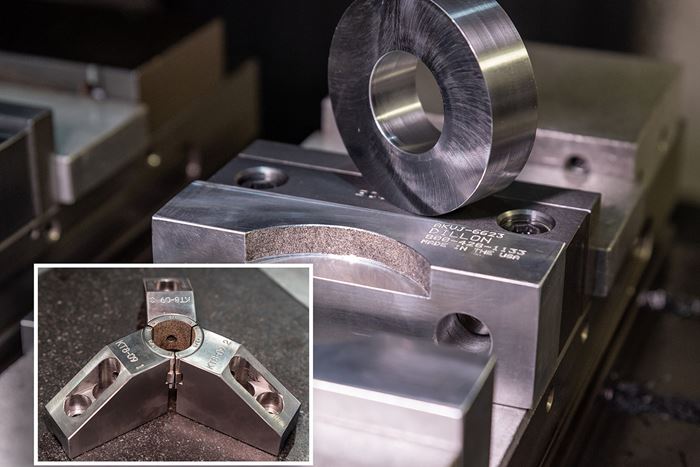

Dillon Manufacturing Provides Top Jaws With Custom Dimensions

Dillon’s custom, special or modified hard-, soft- or full-grip top jaws are said to be compatible with virtually any chuck manufacturer.

FAQ: Workholding

What is workholding?

Workholding refers to any device that is used to a secure a workpiece against the forces of machining. The most basic workholding device is a simple clamp, but workholding can also involve complex fixtures that are custom-built for particular parts. Other common workholding devices include vises and chucks, as well as indexers or rotary tables that are able to change the part’s position while it is held, so the machine can reach various features.

When should you use flexible workholding?

For shops that handle short-run and one-off jobs, flexible workholding is key to producing work cost-effectively. This might involve quick-change workholding that speeds setups, or solutions that leave the sides of parts free for machining, requiring fewer setups.

When should you use automation-ready workholding?

As more shops add automation, they will need workholding systems that are compatible with the systems they’ve implemented, whether they’re robots, pallet systems or something else.

When should you use ID Workholding?

ID workholding, such as expanding mandrels, has a number of benefits and is suited to a range of applications. These fixtures can provide full access to a part’s OD, providing a rigid, even hold that increases accuracy.

What are some tips to consider when using five-axis workholding?

1. Size the Five-Axis Machine Correctly

2. Consider Augmenting Dovetails

3. Get Out of Your Comfort Zone

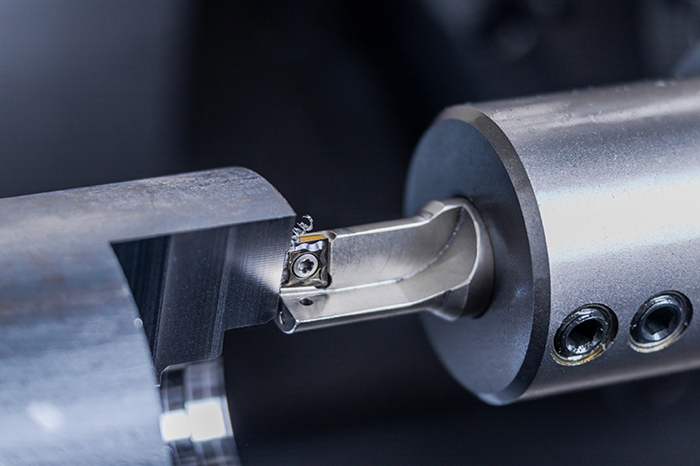

What is a collet chuck?

The collet chuck is an alternate workholding device that, like the jaw chuck, also uses mechanical force to hold the part being turned. While a collet chuck lacks the capacity for the same wide range of workpiece sizes that a jaw chuck can accommodate, it offers advantages related to speed, accuracy and productivity that may be crucial for certain jobs.

Source: When To Use A Collet Chuck

Workholding Suppliers

Narrow by Workholding Category

- Actuators, Hydraulic & Pneumatic

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Angle & Sub Plates

- Arbors, Expandable Workholding

- Centers, Live & Other

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Diaphragm

- Chucks, Gear

- Chucks, Index

- Chucks, Jaw Type

- Chucks, Magnetic

- Chucks, Power

- Chucks, Precision

- Chucks, Self-Contained

- Chucks, Special

- Chucks, Vacuum

- Clamps & Fixturing Devices

- Collets for Workholding

- Dividing & Indexing Heads

- Fixturing Systems

- Guide Bushings (for Swiss Lathes)

- Indexers & Rotary Tables

- Mandrels

- Pedestal Type Fixtures & Tombstone Blocks

- Steady Rests

- Vises & Vise Jaws

- Workholding, Custom

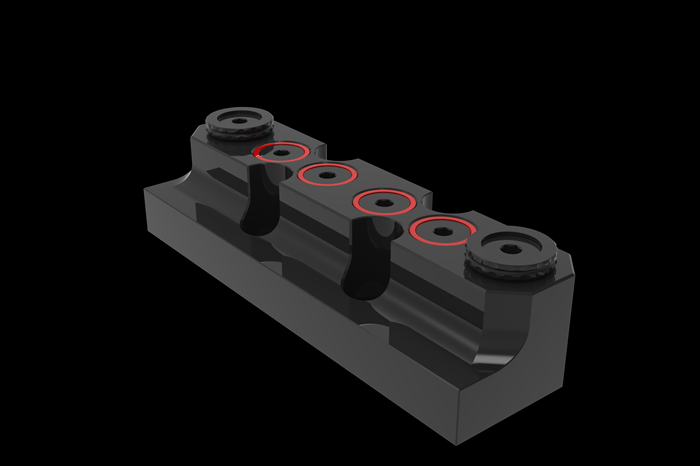

Simple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Dillon's Full-Grip Chuck Jaws Reduce Part Distortion

Dillon Full-Grip Jaws are ideal for high-speed machining, as well as precision boring, tapping, drilling and finishing across most industrial markets.

Dillon Soft Jaw Blanks Feature Milled Surface

Dillon jaw sets reduce set-up times, aid concentric performance, provide better chuck balance and enable longer jaw life because of the increased jaw accuracies.

SMW Autoblok Introduces Custom Setup Stations for Machine Tools

The company’s custom setup stations offer complete interchangeability across all machines with a common interface.

Jergens Inc. Introduces Cast Iron Tooling Columns

The cast iron tooling columns are said to increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs.

Palmgren Vises Enable Five-Sided Access to Workpieces

Palmgren’s Five-Axis Machine Vises are equipped with self-centering jaws that reduce clamping time and provide a workholding solution for a variety of workpieces, including square, round or odd-shaped parts.

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.