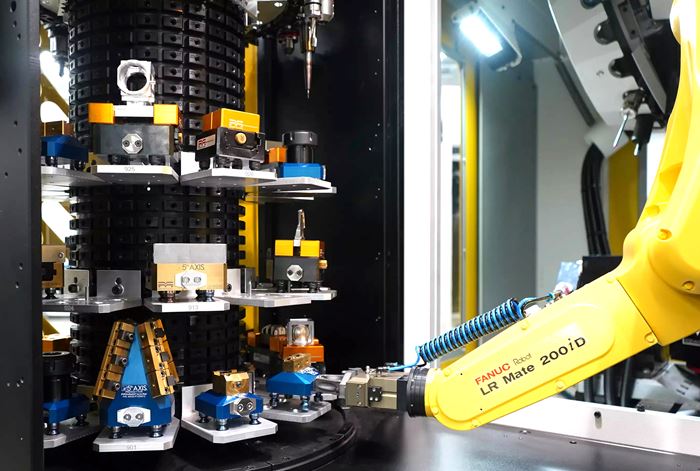

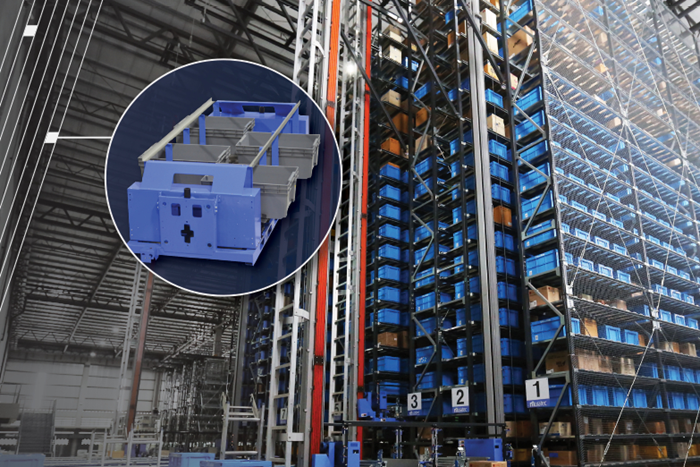

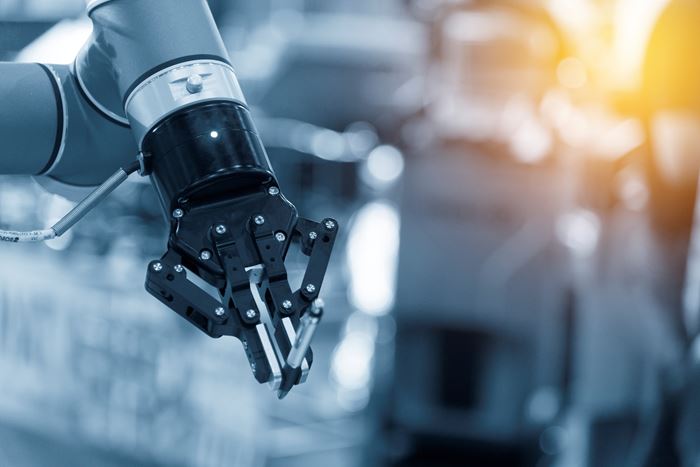

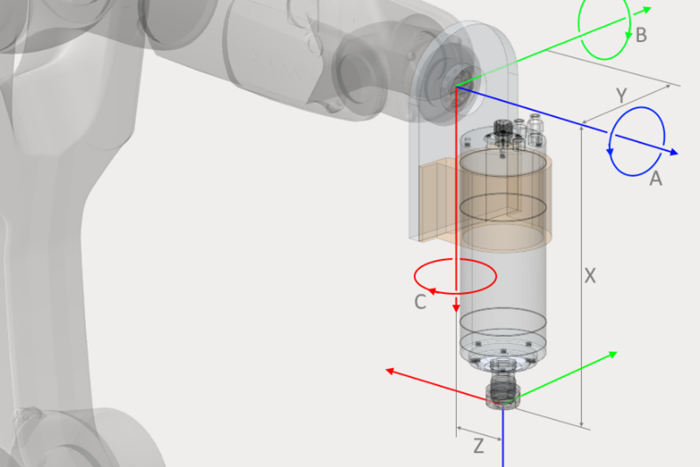

Machine-tending robots are often key components used to enable unattended or lights-out machining operations, adding capacity by taking advantage of time that’s currently unused, like nights and weekends. In many cases, robot integration enables shopfloor employees that were previously loading and unloading parts from machines to perform duties of greater value. Plus, today’s robots are faster and more intelligent than in years past and are also becoming increasingly viable for small-batch/high-mix production. In addition, collaborative robots, or “cobots,” use sensor technology that enables them function safely alongside humans in a shared work environment. That means no more isolating fencing is needed to separate worker and robot.

How Automation Boosts Output in High-Mix Environments

Machine shops of almost any size and production mix can automate machining operations. The key is selecting the right technology to fit the need and working with a reliable supplier to deliver planned performance. The result will be more opportunities for your shop to increase capacity, revenue, and profit.

Automation: Essential Reading

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Okuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Hypertherm Partners With Sofos Robotics on Offline Programming

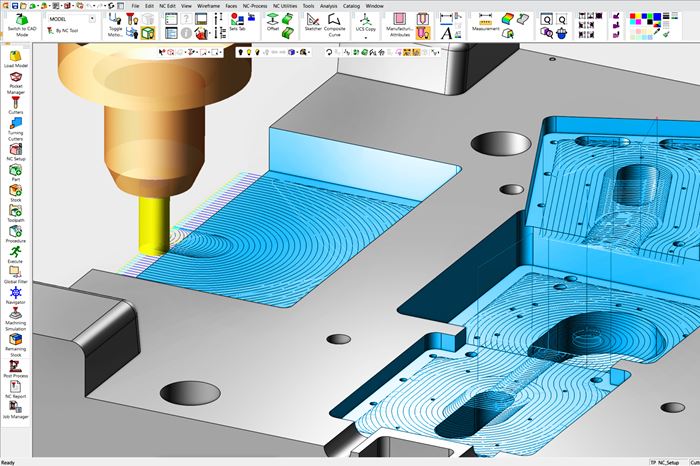

Sofos Robotics uses Robotmaster to perform cell design, reach and feasibility studies, as well as programming services.

168 Manufacturing's Coolant System Automates Delivery

PMTS 2023: FullShop systems monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low.

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.

FAQ: Automation

What is automation?

“Robot” is the first picture that comes to mind, but it means more than that. Automation could be machines that are able to do more in one setup, one handling. It also refers to other options like pallet systems for moving work around, in and out of machines. It refers to software that can automate certain operations. Automation is not a replacement or an alternative for people.

What is a cobot?

A collaborative robot or “cobot” is a robot that is safe to run unguarded near people. Most cobots are safe because they are speed- and force-limited, and they stop upon sensing contact with an obstacle. Cobots are also easy to relocate and reprogram for different tasks in a shop.

What should you know about cobots?

1. Cobots, vision and AI all go together.

2. Cobots do not guarantee safety.

3. Cobot applications need not feature collaboration.

4. Automation’s payback period is declining.

5. Trends in manufacturing favor collaboration.

6. Cobot adoption might be held back by lack of people.

7. Advancing AGV technologies make cobots mobile.

8. Attention recognition is coming.

9. Collaborative can be done in different ways.

10. “Collaborative” can be a bigger idea.

How do robots and 3D printing intersect?

1. 3D Printed End-of-Arm Tooling (EOAT)

2. 3D Printed Off-Robot Accessories

3. Robot-Tended 3D Printers

4. Robots As 3D Printing Systems

Shop Replaces Two Verticals With One Horizontal

By trading two VMCs in to help finance the purchase of a new HMC, this shop was able to significantly increase production and move to lights-out machining.

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

Okuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

Hypertherm Partners With Sofos Robotics on Offline Programming

Sofos Robotics uses Robotmaster to perform cell design, reach and feasibility studies, as well as programming services.

168 Manufacturing's Coolant System Automates Delivery

PMTS 2023: FullShop systems monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low.

#pmts #metalworkingfluids

Grinding Technology Prepares Manufacturers for Business Challenges

Studer’s automation solutions, S100 flexible grinding machine and intelligent coolant system can help users with unattended machining, machining a range of workpieces and saving energy.