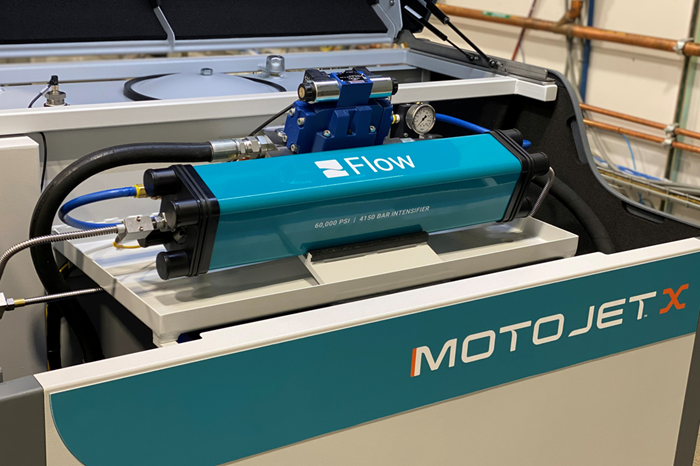

In waterjet cutting, the material removal operation can be described as a supersonic erosion process. It is not pressure but steam velocity that tears away microscopic pieces or grains of material. To achieve high-stream velocity, the pressurized water passes through a tiny hole in a jewel that is affixed to the end of the plumbing tubing. Lasers are systems for the generation and amplification of light, where “light” can refer to any electromagnetic wavelength. In its simplest form, a laser consists of a gain medium, a method of pumping the gain medium and an optical cavity.

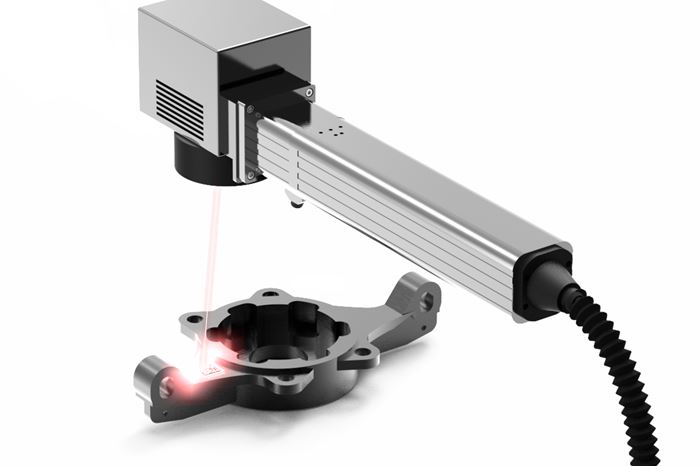

What is Laser Cleaning? How Does it Work? EMAG Experts Explain

Lasers provide the flexibility to clean some areas of a CNC-machined workpiece while leaving others untouched.

Laser & Waterjet: Essential Reading

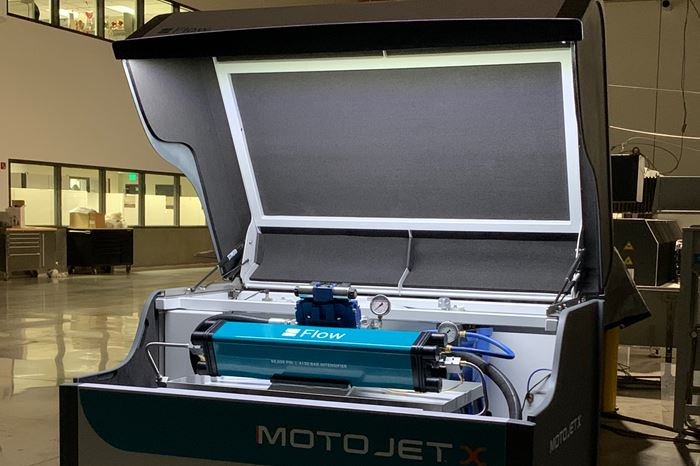

TCI Precision Metals Adds Waterjet Machining Center

The new machine is the second waterjet TCI Precision Metals has added in the last twelve months to keep up with growing demand for precision Machine-Ready Blanks and other specialty parts.

Cincinnati Incorporated Introduces Compact Fiber Laser

According to Cincinnati Incorporated, the CLi is an ideal starting laser that has all the functions necessary for shops that want to make parts rather than outsource.

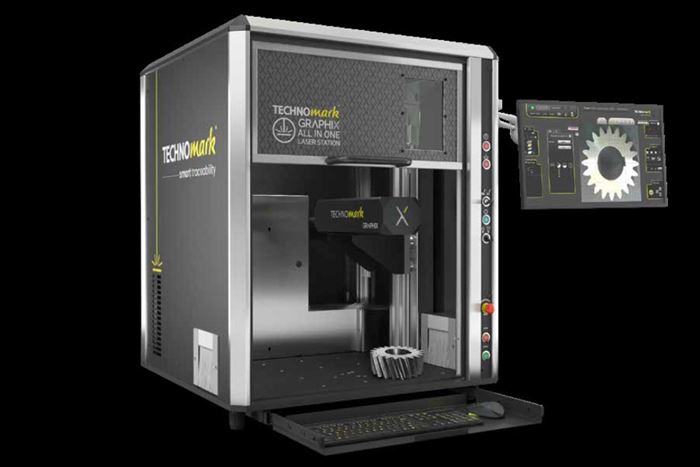

A Marked Part Is Never Lost

Laser engraving parts has become an essential process at MRS Machining. Marked parts mean that both the manufacturer and the customer are protected from misidentifying parts.

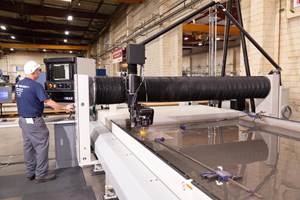

Machining 101: What is Waterjet Cutting?

Waterjet cutting may be a simpler machining method, but it packs a powerful punch that requires operators to stay cognizant of multiple parts’ wear and accuracy.

AMEXCI and SLM Solutions Partner to Promote Metal AM

AMEXCI and SLM Solutions have partnered to promote industrialization of metal additive manufacturing, starting with AMEXCI’s investment in the SLM 500.

FAQ: Laser & Waterjet

What is laser cutting?

Laser micromachining includes processes like laser ablation, where the laser energy penetrates the material and leads to some transformation. Laser ablation is the direct removal of material resulting from the interaction of the laser light with the sample. Most commonly, ablation relies on the laser light being absorbed in the material, leading to material interaction.

Source: Modern Machine Shop’s Handbook for the Metalworking Industries

What is waterjet cutting?

Waterjet cutting, at its simplest, is the process of a high-pressure jet of water cutting into a material. The technology often compliments other machining techniques such as milling, laser, EDM and plasma. No hazardous material or vapors form during the waterjet process, and neither do heat-affected zones or mechanical stresses. Waterjet can cut whisper-thin details in stone, glass and metals; quickly drill holes in titanium; cut food; and even kill pathogens in beverages and dips.

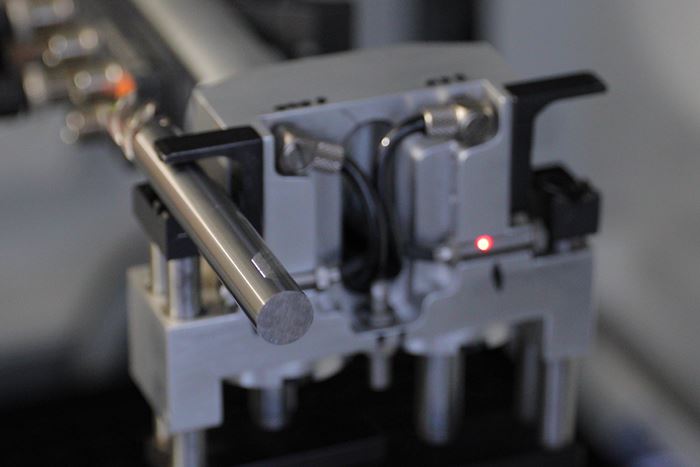

What are potential errors to watch for with waterjet cutting?

Potential errors affecting accuracy include cutter compensation error, programming error and machine motion.

Cutter compensation is the value entered into the control system to take into account the width of cut from the jet — that is, the amount by which the cut path must be enlarged so the final part comes out the proper size. To avoid potential errors in high-precision work, the operator should conduct test cuts and know the frequency at which cutter compensation must be adjusted to match mixing tube wear.

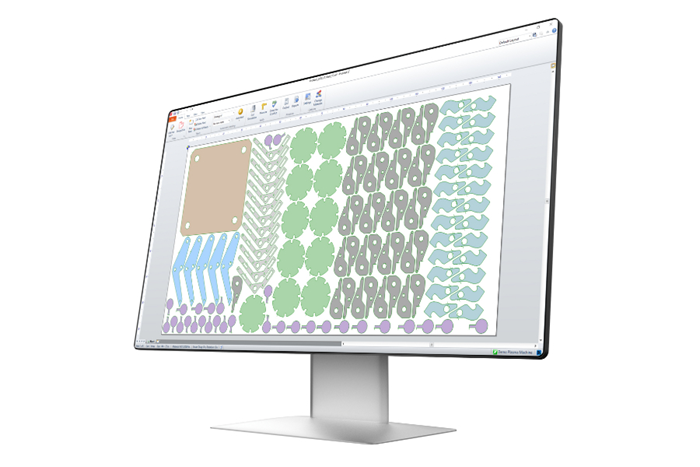

Programming errors arise most often because some XY controls do not show dimensions on part programs, making lack of dimensional matching between the part program and the CAD drawing difficult to detect. Important aspects of machine motion that can introduce errors are backlash in the mechanical unit and repeatability.

Laser & Waterjet Suppliers

Weep Not, Waterjet Machine. Predictive Maintenance is Here.

The versatility of waterjet cutting is well known, but its reputation as a maintenance intensive technology holds it back. Predictive maintenance may change that.

#Basics

Omax Waterjet Designed for Ease of Use

The OptiMax waterjet system from Omax is designed to be a versatile, easy-to-use system with optimized software, system monitoring and more.

What is Laser Cleaning? How Does it Work? EMAG Experts Explain

Lasers provide the flexibility to clean some areas of a CNC-machined workpiece while leaving others untouched.

#Basics

TCI Precision Metals Adds Waterjet Machining Center

The new machine is the second waterjet TCI Precision Metals has added in the last twelve months to keep up with growing demand for precision Machine-Ready Blanks and other specialty parts.

Cincinnati Incorporated Introduces Compact Fiber Laser

According to Cincinnati Incorporated, the CLi is an ideal starting laser that has all the functions necessary for shops that want to make parts rather than outsource.

A Marked Part Is Never Lost

Laser engraving parts has become an essential process at MRS Machining. Marked parts mean that both the manufacturer and the customer are protected from misidentifying parts.

Machining 101: What is Waterjet Cutting?

Waterjet cutting may be a simpler machining method, but it packs a powerful punch that requires operators to stay cognizant of multiple parts’ wear and accuracy.

#Basics