Laser Cutting Machine Offers Nano-Range Surface Finish

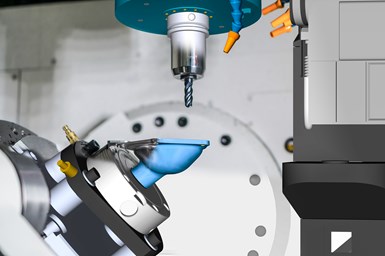

Rollomatic’s LaserSmart LS510 cutting and ablation machine is designed to produce sharp corner radii in hard materials like PCBN material.

Rollomatic’s LaserSmart LS510 cutting and ablation machine is designed to deliver a “super-mirror” finish, particularly in hard materials.

The machine is designed to produce sharp corner radii in the PCD/CBN industry, with a maximum radius on the cutting edge below 0.5 micron. In addition, it can consistently produce a defined radius of 3, 6 and 9 microns. The machine can accommodate round-shaft tools as well as HSK63 shanks.

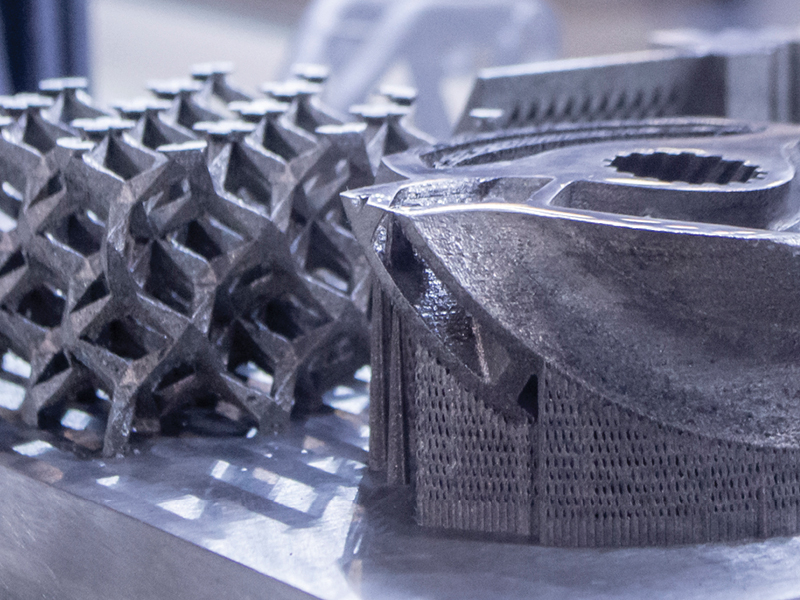

According to the company, the strategy for this machine is to offer a cost-effective solution for producing high quality cutting tools from polycrystalline diamond (PCD), cubic boron nitride (CBN) and chemical vapor deposited (CVD) cutting tools which traditionally require a double-process of spark erosion and polish grinding.

Features of the machine include up to four times faster feedrates with identical edge and surface quality, 3D machining of drill points and endmill cutting geometries and a process to sharpen the cutting edge of CVD or thick-film diamond coated cutting tools. It implements linear motion technology on all linear and rotary axes to support highly accurate trajectories for complex cutting paths.

Rollomatic says fine-laser cutting achieves a superfine cutting edge with a surface finish that is unachievable by traditional grinding/EDM. According to the company, conventional grinding with diamond wheels risks “pulling out” an entire PCD crystals, while laser cutting slices through the crystal, leaving a portion in the matrix, providing a sharp cutting edge.

Sharper cutting edges and superior surface quality on PCD tools deliver longer tool life and higher feed rates during machining, the company says. Laser ablation allows flexibility to optimize tool geometries. Manufacturing chip form geometries in PCD can be performed by this machine using the ablation process as an alternative to existing methods.

RELATED CONTENT

-

Weep Not, Waterjet Machine. Predictive Maintenance is Here.

The versatility of waterjet cutting is well known, but its reputation as a maintenance intensive technology holds it back. Predictive maintenance may change that.

-

The Promise of Waterjet Technology for Micromachining

The potential benefits of using waterjet technology to produce parts or part features smaller than 300 microns are compelling. Developers and researchers are getting close to breaking the barriers that stand in the way of micromachining in the 150- to 200-micron range and below.

-

How To Choose A Plasma Cutter

Contributed by Hypertherm (West Lebanon, New Hampshire). The company designs and manufactures plasma cutting systems for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes handheld and mechanized plasma systems and consumables, as well as CNC motion and height controls.

.JPG;width=70;height=70;mode=crop)

%20(1).1676494398075.png)