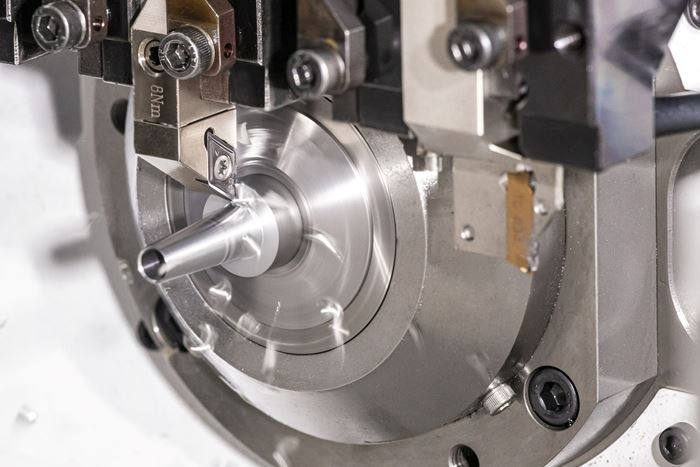

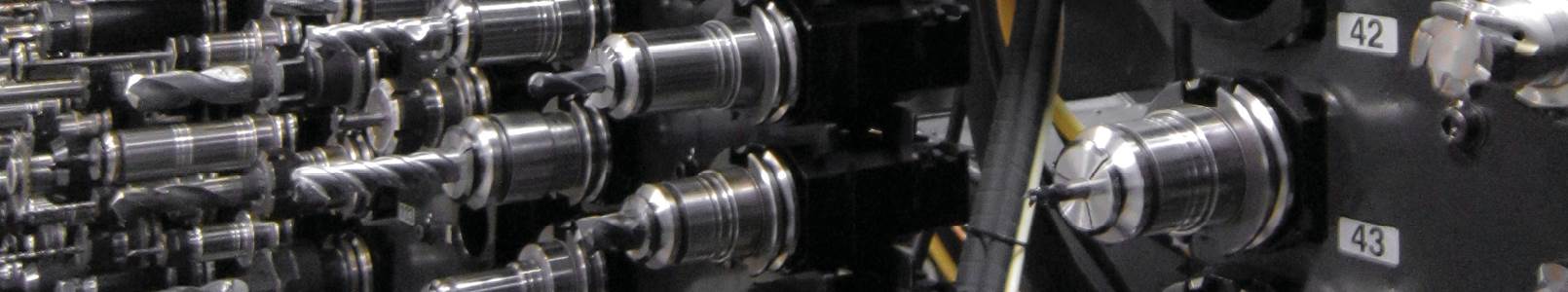

The Toolholder is the essential connection between the machining center and the cutting tool. The toolholder fits into and is secured by the machining center’s spindle, and in turn, secures the cutting tool such as a drill or end mill by clamping onto its shank. The taper of the toolholder matches the toolholder interface of the particular spindle. Toolholder tapers are often conical, including CAT and BT taper specifications. A different kind of taper, HSK, is not tapered at all, but instead includes a variety of flanges for securely locking the toolholder in place. Toolholders use different mechanisms for clamping the tool including set screw, collet, hydraulic compression and shrink-fit.

Quick Change Tooling Line Designed for Swiss-Type

IMTS22: Iscar releases the NEO Swiss Modular Quick Change Tooling Line to promote repeatability from job to job through strategic design.

Toolholders: Essential Reading

Rego-Fix Celebrates 50th Anniversary of the Original ER Collet

In 1972, Rego-Fix developed and manufactured the original ER Collet.

Service to Rebuild Tool Holders in North America

Index Corp. now offers a service to rebuild toolholders in North America.

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Kaiser Tool Company Releases Swiss Angled Toolholder Line

ThinBit from Kaiser Tool Company expands into Swiss Angled Toolholders, which are available in a variety of hard coatings as well as uncoated.

GenSwiss Releases Redesigned Toolholding System

Its GenQuick quickchange ER system for Swiss-type CNC machines and precision machining equipment has been updated.

FAQ: Toolholders

What is a HSK toolholder?

HSK, meanwhile, works by elastically deforming the toolholder. Fingers inside the hollow shank of the toolholder clamp the holder by pushing out. High spindle speed helps this interface, because the centrifugal force strengthens this clamping.

Source: Testing Measures Impact of Toolholder Interface Rigidity

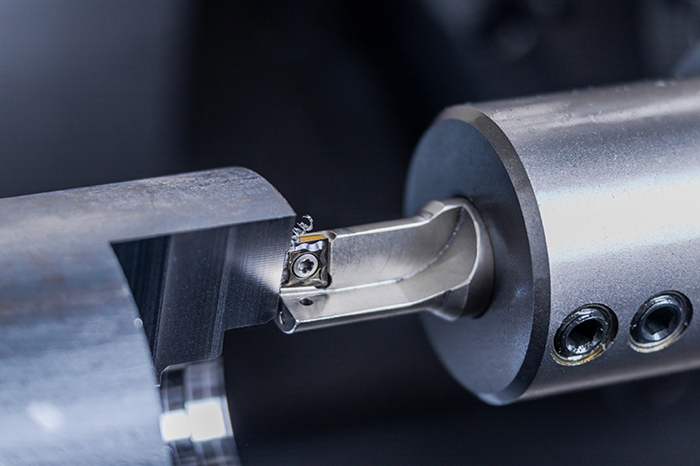

How does a hydraulic toolholder work?

The hydraulic toolholder works by using fluid to compress an internal membrane within the holder body. The hydraulic fluid delivers uniform pressure around the membrane allowing it to compress equally around the periphery of the cutting tool. Basically, that’s how the hydraulic toolholder delivers its high concentricity specs.

Source: Why Use Hydraulic Toolholders

What is a toolholder?

The toolholder is the connection between the machining center and the cutting tool, employing clamping mechanisms such as set screws, collets, and shrink-fit.

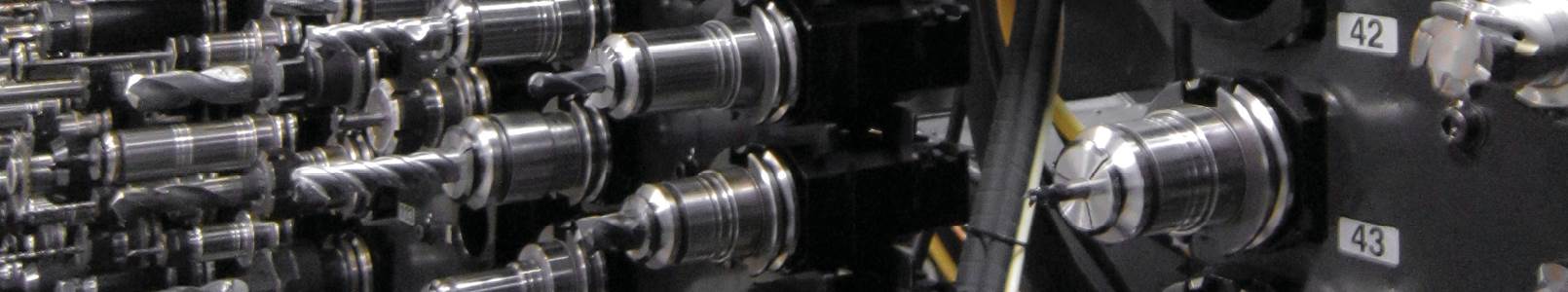

Toolholders Suppliers

Narrow by Toolholders Category

Haimer USA Models a Streamlined Toolroom

Haimer USA is celebrating its 20th anniversary with a live demonstration of its digital toolroom. Find out more past the aluminum panther.

#imts

Quick Change Tooling Line Designed for Swiss-Type

IMTS22: Iscar releases the NEO Swiss Modular Quick Change Tooling Line to promote repeatability from job to job through strategic design.

#imts

Rego-Fix Celebrates 50th Anniversary of the Original ER Collet

In 1972, Rego-Fix developed and manufactured the original ER Collet.

Service to Rebuild Tool Holders in North America

Index Corp. now offers a service to rebuild toolholders in North America.

All-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

#successionplanning #workforcedevelopment

Kaiser Tool Company Releases Swiss Angled Toolholder Line

ThinBit from Kaiser Tool Company expands into Swiss Angled Toolholders, which are available in a variety of hard coatings as well as uncoated.