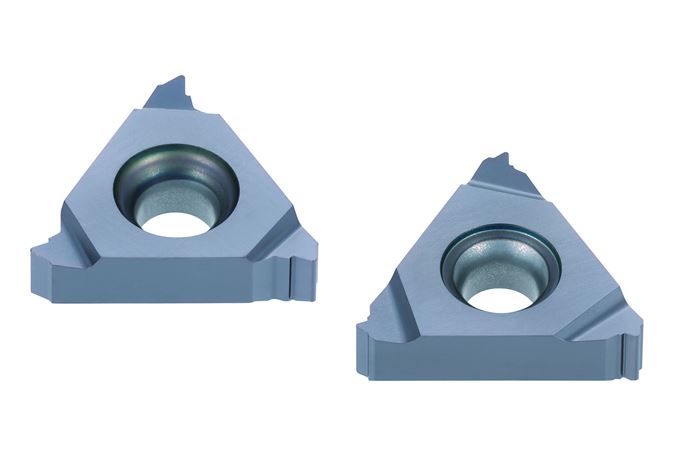

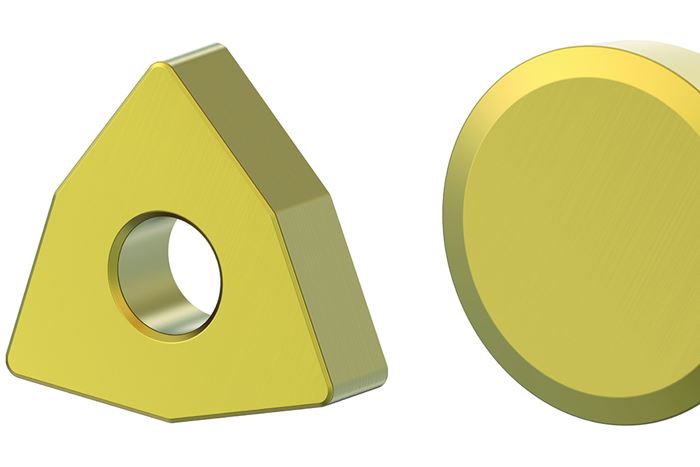

Turning involves a fixed and non-rotating cutter, because in turning, the workpiece spins instead of the tool. Turning tools typically consist of a replaceable insert in a turning tool body. The insert can be distinctive in a number of ways, including shape, material, coating and geometry. The shape can be round to maximize edge strength, diamond-shaped to allow a sharp point to cut fine features, square, or even octagonal to increase the number of separate edges that can be applied as one edge after another wears out. The material is typically carbide, though ceramic, cermet or diamond inserts can be applied to more demanding applications. A variety of protective coatings also help these insert materials cut faster and last longer.

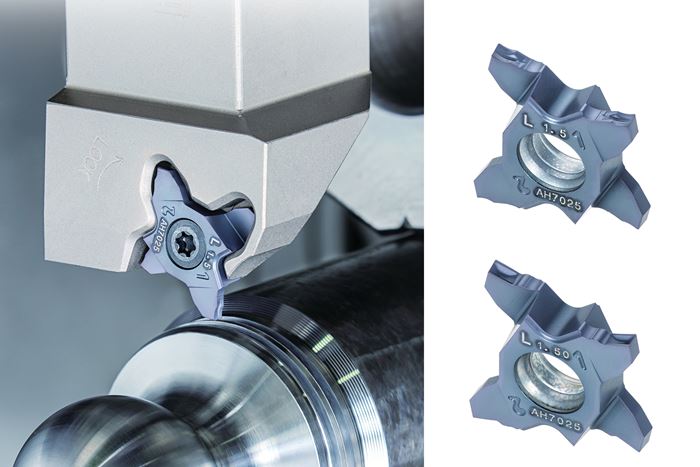

Multi-Directional Turning With New Turning Concept

Tungaloy’s AddMultiTurn provides the flexibility for outer diameter, face and profile turning operations in multi directions, which include high-feed back (pull) turning method, enabling toolpaths that turn in the opposite direction of conventional turning process at higher feeds.

Turning Tools : Essential Reading

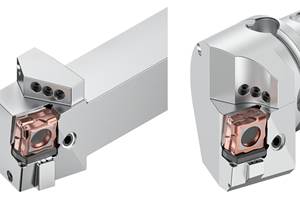

New Kennametal Turning System Has Eight Cutting Edges Per Insert

Kennametal’s Fix8 turning system is said to increase productivity of heavy-duty turning operations while providing the lowest cost per edge and reducing cutting forces up to 15%.

Palmgren's Bench Lathe Handles a Variety Operations

Palmgren’s new 9" × 20" bench lathe is constructed from heavy cast iron and reportedly features a smooth power transmission, precision thrust and ball bearings in the head stock and spindle as well as hardened and ground ways.

Live Tool Speed Increaser Spurs Engraving Cost Savings

By using a Heimatec speed increaser provided by Platinum Tooling, Kurt Machining was able to achieve ninefold cost savings for a project engraving 6060 aluminum.

New Coated Turning Grades From Sumitomo

Eastec 2021: The new grades feature heat-resistant, cemented carbide base material, which Sumitomo claims has excellent high-temperature hardness and strength.

Machining 101: What is Turning?

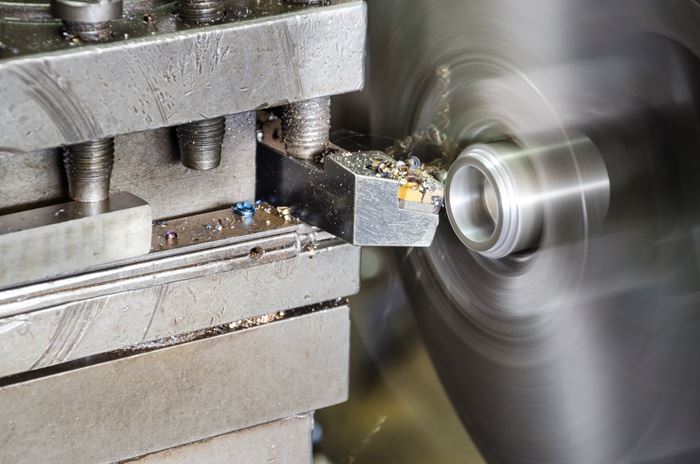

Turning uses a lathe to remove material from the outside of a rotating workpiece, while boring does the same from the inside of a rotating workpiece.

FAQ: Turning Tools

What is turning?

Turning is the process of using lathes to remove material from the outer diameter of a rotating workpiece. Single-point tools shear metal from the workpiece in (ideally) short, distinct, easily recyclable chips.

Source: Machining 101: What is Turning?

How do you sharpen turning tools?

Early turning tools were solid, rectangular pieces of high-speed steel with rake and clearance angles on one end. When the tool dulled, machinists would sharpen it on a pedestal grinder for reuse. High-speed steel tools are still common on older turning machines, but carbide has become more popular, especially in brazed single-point form. Carbide sports better wear resistance and hardness, leading to better productivity and tool life, but it is more expensive and requires expertise to resharpen.

Source: Machining 101: What is Turning?

What is cutting feed and speed?

Turning is a combination of linear (tool) and rotational (workpiece) movement. Thus, cutting speed is defined as the rotational distance (recorded as sfm — surface feet per minute — or smm — square meters per minute — traveled in one minute by a point on the part surface). Feed rate (recorded in inches or millimeters per revolution) is the linear distance that the tool travels along or across a workpiece surface. Feed is also sometimes expressed as the linear distance the tool travels in a single minute (in./min or mm/min).

Feed rate requirements vary depending on the operation’s purpose. In roughing, for example, high feeds are generally better for maximizing metal removal rates, but require high part rigidity and machine power. Finish turning, meanwhile, might slow down the feed rate to produce the surface finish specified on the part blueprint.

Source: Machining 101: What is Turning?

What is boring?

Boring is primarily used for finishing large, cored holes in castings or pierced holes in forgings. Most tools are similar to those in traditional, external turning, but cutting angles are particularly critical due to chip flow concerns.

Source: Machining 101: What is Turning?

What is a spindle?

The spindle on a turning center is either belt-driven or direct-drive. Generally, belt-driven spindles represent older technology. They speed up and slow down at a lower rate than direct-drive spindles, which means cycle times can be longer. If you’re turning small-diameter parts, the time it takes to ramp the spindle from 0 to 6,000 rpm is significant. In fact, it might take twice as long to reach this speed than with a direct-drive spindle.

A small degree of positional inaccuracy may occur with belt-driven spindles, because the belt between the drive and the positional encoders creates a lag. With integral direct-drive spindles, this is not the case. Ramping up and down with a direct drive-spindle happens at a high rate, and the positional accuracy also is high, a significant benefit when using C-axis travel on live-tooling machines.

What is the function of a tailstock on a lathe machine?

A built-in, numerically controlled tailstock can be a valuable feature for automated processes. A fully programmable tailstock provides more rigidity and thermal stability. However, the tailstock casting adds weight to the machine.

There are two basic types of programmable tailstocks — servo-driven and hydraulic. Servo-driven tailstocks are convenient, but the weight they can hold may be limited. Typically, a hydraulic tailstock has a retractable quill with a 6-inch stroke. The quill also can be extended to support a heavy workpiece, and do so with more force than a servo-driven tailstock can apply.

Turning Tools Suppliers

Narrow by Turning Tools Category

- Boring Tools for Turning Machines

- Boring Tools

- Chamfering Tools

- Burnishing Tools (Roller)

- Broaching Tools

- Counterbores/Countersinks

- Cut-Off Tools/Attachments

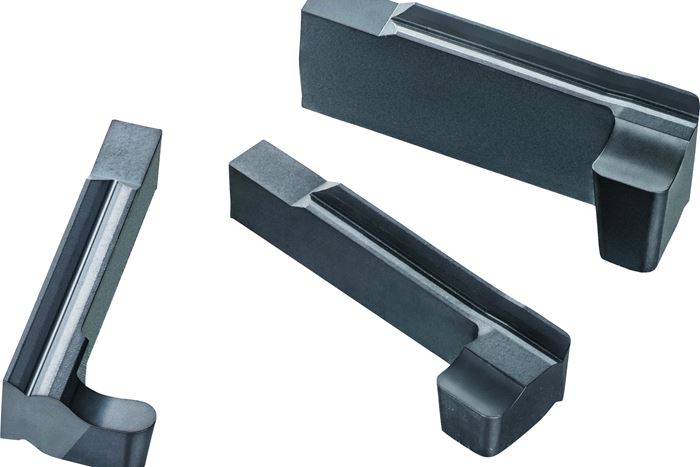

- Grooving Tools

- Honing & Lapping Tools

- Gear Cutting Tools

- Drills

- Drill Chucks

- Drill Bushings

- Diamond Tools

- Arbors (for Cutters)

- Reamers

- Saw Blades

- Shaving Tools

- Tooling Materials, Carbides

- Tooling Materials, Ceramics

- Tooling Systems, Modular and/or Quick-Change

- Toolholders

- Tool Storage & Handling Systems

- Tool Repair, Coating & Treatment Services

- Tool Presetters

- Tool Conditioning Equipment

- Tool Condition Monitoring Systems

- Tool Blanks

- Tap Drivers & Attachments

- Spline Inserts

- Slotting Saws

- Serration Tooling

- End Turning Machines

- Lathes, Cut-Off

- Lathes, Cycle-Controlled (Semi-CNC or "Teachable")

- Lathes, Manual

- Turn/Mill Machines, CNC

- Turning Centers, Horizontal, CNC

- Turning Centers, Inverted Vertical, CNC

- Turning Centers, Twin-Spindle/Twin-Turret

- Turning Centers, Vertical, CNC

- Tooling Materials, Ceramics

- Tooling Materials, Carbides

4 Questions To Ask When Moving to Live Tooling

Live tooling is often seen as a niche solution, but there are a number of different processes that are improved by introducing live tooling.

#Basics

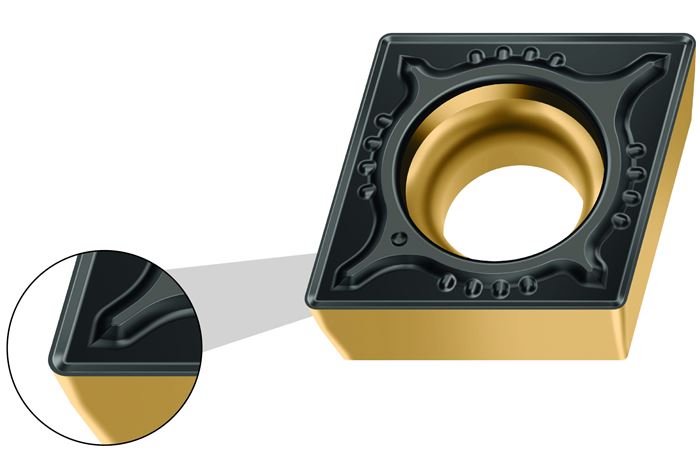

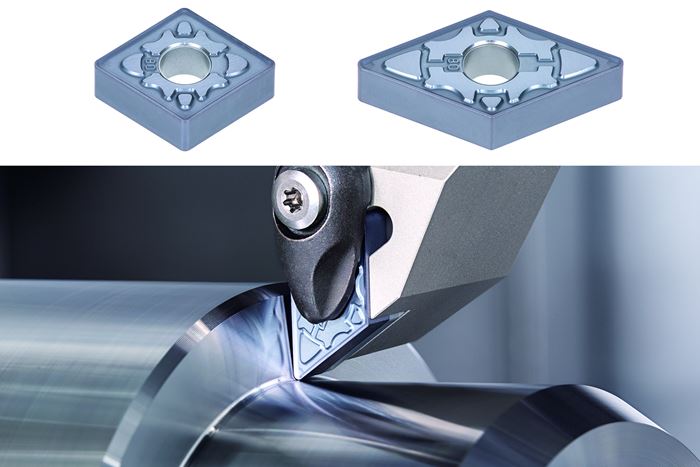

Ceratizit Offers Inserts Optimized for Steel Turning

Three new, standard, coated-carbide, ISO-P steel inserts from Ceratizit are each optimized for specific production conditions.

Multi-Directional Turning With New Turning Concept

Tungaloy’s AddMultiTurn provides the flexibility for outer diameter, face and profile turning operations in multi directions, which include high-feed back (pull) turning method, enabling toolpaths that turn in the opposite direction of conventional turning process at higher feeds.

New Kennametal Turning System Has Eight Cutting Edges Per Insert

Kennametal’s Fix8 turning system is said to increase productivity of heavy-duty turning operations while providing the lowest cost per edge and reducing cutting forces up to 15%.

Palmgren's Bench Lathe Handles a Variety Operations

Palmgren’s new 9" × 20" bench lathe is constructed from heavy cast iron and reportedly features a smooth power transmission, precision thrust and ball bearings in the head stock and spindle as well as hardened and ground ways.

Live Tool Speed Increaser Spurs Engraving Cost Savings

By using a Heimatec speed increaser provided by Platinum Tooling, Kurt Machining was able to achieve ninefold cost savings for a project engraving 6060 aluminum.

#casestudy

New Coated Turning Grades From Sumitomo

Eastec 2021: The new grades feature heat-resistant, cemented carbide base material, which Sumitomo claims has excellent high-temperature hardness and strength.