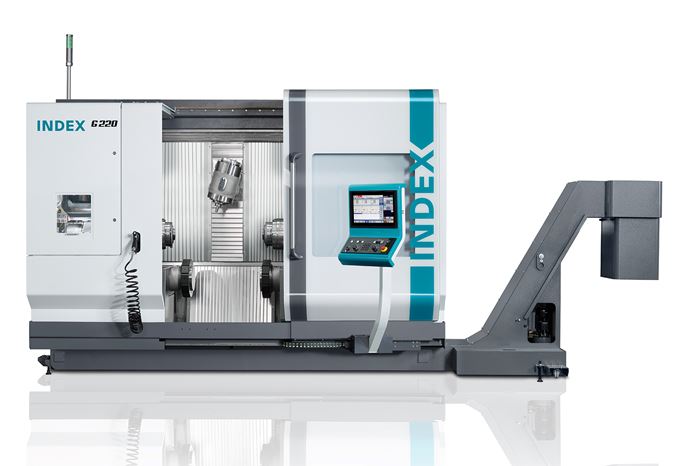

Turn/Mill Machines are capable of both rotating-workpiece operations (turning) and rotating-tool operations such milling and cross-drilling. The machine is typically recognizable as a horizontal or vertical lathe, with spindles for milling and drilling simply available at some or all of the tool positions. A part requiring a variety of operations can be machined in one setup, particularly if a subspindle allows the part to be passed from one spindle to another during machining. More recently introduced turn/mill machines depart from the lathe design into something much more like a hybrid machine—combining a lathe’s chucks and spindles with the travels and milling power of a machining center.

Building an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Turn/Mill: Essential Reading

A Career at the Top Helps Rebuild a Job Shop

A new approach to management propels expansion into Swiss-type and multitasking machining work.

Automated Multitasking Machine Drops Parts Complete

This automated multitasking machine with an integrated robot eliminates the need to run parts across multiple machines, saving floor space, setup time and labor.

Turn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

Digitalization and Multitasking Accelerate Prototyping

Protolabs’ Mazak Integrex multitasking machines facilitate efficient automation of the prototyping company's high-mix, low-volume workload.

Methods Launches Twin-Turret Multitasking Machine

Operators can use the Nakamura-Tome SC-100X2’s twin turrets for superimposed machining or twin-spindle machining, achieving high speed and precision with both.

FAQ: Turn/Mill

What is a multitasking machine?

Multitasking machines are often built on a turning center platform. These machines use rotary tools to combine several cutting processes such as turning, milling, drilling, tapping, grooving, threading and deep-hole boring on one machine.

Source: Buying a Lathe: Slant-Beds and Multitasking Configurations

What is a turn/mill machine?

A mill/turn machine, or turn/mill machine, is a CNC machine that can perform turning and milling operations.

Why use a multitasking machine?

Why do these machines continue to rise in popularity? It’s simple. They offer the opportunity for a part to be machined completely on one piece of equipment.

Traditionally, parts that might start on a lathe for turning work, for example, could then have to be taken to a mill to create prismatic features. That means, two machines must be set up and tended to. Parts with turning work complete must be transported to the mill. Those parts might have to be staged as work in process (WIP) waiting for the mill to become available (and scheduling can be tricky to efficiently coordinate machine availability). An accumulating number of setups and part repositioning can lead to error stacking. Multiple machines take up more floor space and consume more energy.

In cases in which a multitasking machine can produce parts complete, these issues go away.

Source: Multitasking Machining Equipment: Now the New Normal

Turn/Mill Suppliers

Narrow by Turn/Mill Category

OEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

#micromachining

Building an Automation Solution From the Ground Up

IMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

#imts

A Career at the Top Helps Rebuild a Job Shop

A new approach to management propels expansion into Swiss-type and multitasking machining work.

#successionplanning #workforcedevelopment

Automated Multitasking Machine Drops Parts Complete

This automated multitasking machine with an integrated robot eliminates the need to run parts across multiple machines, saving floor space, setup time and labor.

Turn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

#Basics

Digitalization and Multitasking Accelerate Prototyping

Protolabs’ Mazak Integrex multitasking machines facilitate efficient automation of the prototyping company's high-mix, low-volume workload.