Whether it’s using drills to make holes, borings bars or reamers to enlarge their IDs, or taps to thread them, this is where to read up about holemaking. Holemaking is a process used to cut a hole in a part or a workpiece.

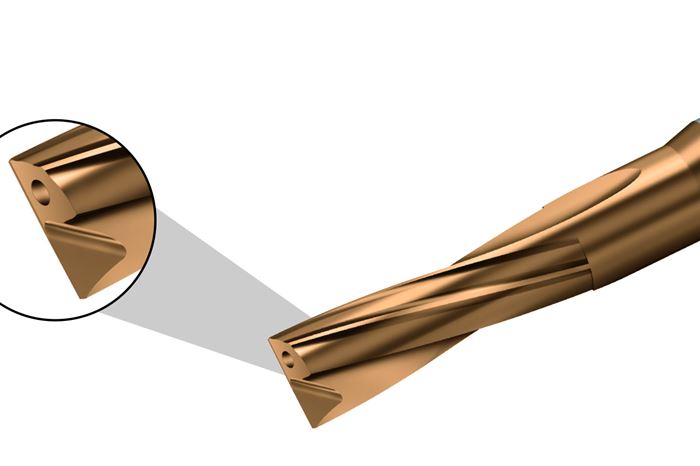

Star SU Launches Custom Gundrill Designed to Reduce Tool Drift

The custom Double-Contour, Single-Flute Gundrill features an extended carbide-length head that reduces tool drift for the length of the cut.

Holemaking: Essential Reading

Tungaloy Expands Drill System With Drill Sleeves

Adding drill sleeves to the standard lineup enhances drilling productivity of Swiss-type sliding-head automatic lathes.

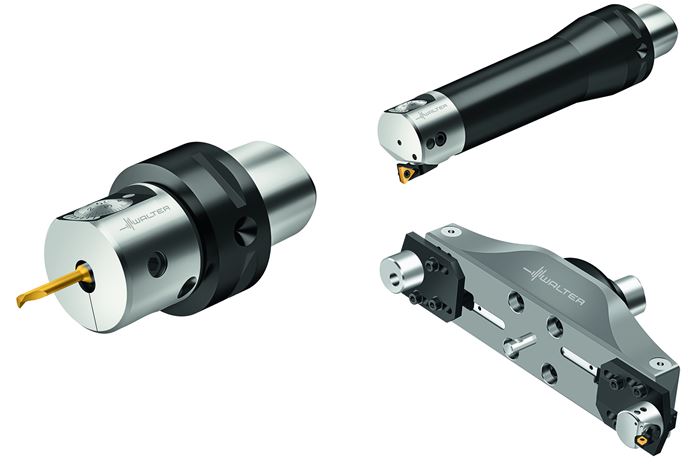

Walter Adds to Line of Precision Boring Tools

These new vibration-free tools provide finish machining of precise bores with high surface quality and are said to be up to three times more reliable and flexible than comparable models.

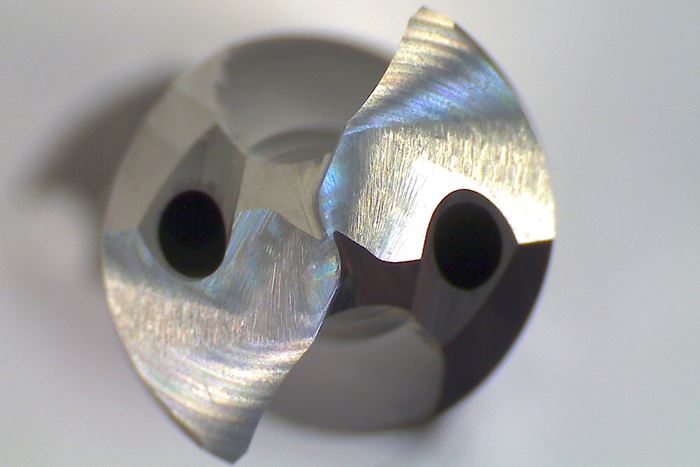

ANCA Creates Solid PCD-Tipped Helical End Mills, Drills

The company’s Edge machine is capable of creating complex 3D cutting tool forms, including solid PCD-tipped end mills and drills under 1 mm.

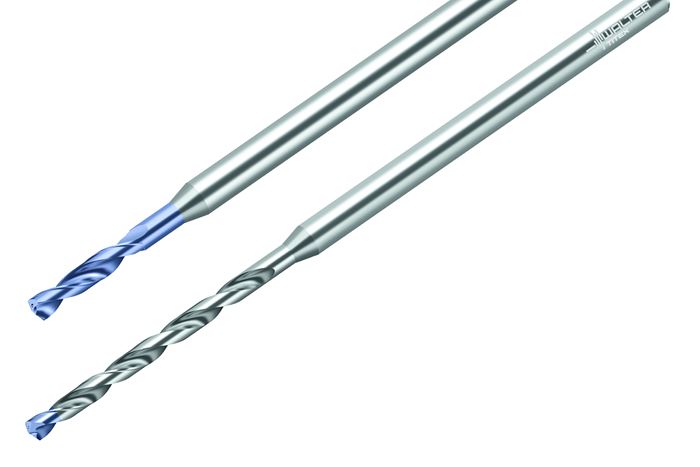

Walter Expands Line of Solid Carbide Milling Cutters, Drills

Walter’s MD173 and MD177 Supreme solid carbide milling cutters feature seven cutting edges. Additionally, the company introduces the DC165 Advance solid carbide drill for non-ferrous and cast iron applications.

How Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

FAQ: Holemaking

What Are Carbide Coatings?

Most modern carbide inserts and solid carbide tools are coated with a thin film (between 3 and 20 microns, or 0.0001 to 0.0007 inch). The coating is typically composed of titanium nitride, aluminum oxide and titanium carbon nitride layers. This coating increases the hardness and creates a heat barrier between the cut and the substrate.

Source: Choosing Your Carbide Grade: A Guide

What is a counterbore?

Counterboring is a machining operation that will enlarge an existing hole’s diameter to a specified depth. Traditionally, counterboring is done with either a special counterboring tool that has a pilot, or it is done with an end mill. In either case, the diameter of the tool (end mill or counterbore) must match the diameter that is counterbored.

Traditional counterboring is great for smaller holes, but as holes get larger, the cutting tools get more expensive.

Source: Custom Macro To Helically Mill A Counterbore

What is countersinking?

A countersink is a functional surface upon which a fastener head bears. Because fastener performance is so important, countersink tolerances are critical.

What is a chamfer?

Hole chamfers are usually specified simply to make it easier to insert a screw, pin, bushing, or other assembly component. The component doesn't bear on the chamfer, so diameter and angle tolerances are usually not critical to the part's performance.

Source: Gaging Countersunk And Chamfered Holes

Holemaking Suppliers

Narrow by Holemaking Category

New Machining Technology Works With Old to Restore WWII Submarine

A set of donated boring bars that can be used in a 1954 boring head will enable volunteer machinists to recreate a pair of binoculars for the USS Pampanito.

Allied Machine & Engineering Expands Range of Boring Tools

Both the 420 (410) and 465 (464) digital boring heads come equipped with a 3ETech docking port for easy digital diameter adjustments.

Star SU Launches Custom Gundrill Designed to Reduce Tool Drift

The custom Double-Contour, Single-Flute Gundrill features an extended carbide-length head that reduces tool drift for the length of the cut.

Tungaloy Expands Drill System With Drill Sleeves

Adding drill sleeves to the standard lineup enhances drilling productivity of Swiss-type sliding-head automatic lathes.

Walter Adds to Line of Precision Boring Tools

These new vibration-free tools provide finish machining of precise bores with high surface quality and are said to be up to three times more reliable and flexible than comparable models.

ANCA Creates Solid PCD-Tipped Helical End Mills, Drills

The company’s Edge machine is capable of creating complex 3D cutting tool forms, including solid PCD-tipped end mills and drills under 1 mm.

Walter Expands Line of Solid Carbide Milling Cutters, Drills

Walter’s MD173 and MD177 Supreme solid carbide milling cutters feature seven cutting edges. Additionally, the company introduces the DC165 Advance solid carbide drill for non-ferrous and cast iron applications.