Automating a time-consuming, intricate process can save a shop time and money while freeing up labor power for other tasks. Sometimes automation looks like a robot or a computer; but sometimes it looks like a counterboring tool with a retracting blade. A back spotfacer from Heule Tool (Loveland, Ohio) removed the need for operators at one machining business to manually detach and reattach the tool’s cutting head, reducing process time by two to three hours per part, on average.

Sicom Industries, which has locations in Houston, Texas, and Vancouver, British Columbia, takes on work for a range of industries including defense, oil and gas, aerospace and mining. Many of the company’s jobs are for small quantities of high-value, precisely machined parts. A burr or imperfection can prevent flawless fit between parts, obstructing oil and gas flow, or abrading them and leading to premature part failure. One process the company frequently performs on these intricate, expensive parts can be intricate and complicated as well. That process is back-spotfacing.

Featured Content

Back-spotfacing is an operation in which a cutting tool reaches through a hole to the far side of a workpiece to finish the area around the hole, cutting back toward the spindle. However, for Sicom, back-spotfacing is not just a finishing step in the manufacturing process, it is vital step in the part’s utility as well.

A typical part requiring this process—an aluminum casting—might have upward of 40 internal cavities. In the past, Sicom’s milling department manager, Nathan Barker, and his team employed a traditional method in which an operator would feed a shaft through a bore and manually attach the cutting head on the other side. The operator would start the spindle, run the tool, and then take the cutting head off before retracting the post. Performing this operation 40 times on one part was time-consuming and required the focus of a skilled operator for hours of repetitive labor.

This was especially true for enclosed cavities. In this scenario, it would be difficult for operators to manually attach the cutting head to the body, making the process even more complicated and time-consuming. Large parts would have to be re-angled and removed from the production line for finishing, which could take several operators out of production for hours. With an average floor rate of $125 per hour, saving time would mean the company could save money and free up labor to work elsewhere in the production line. The key was to find a way to do this while still meeting customers’ specifications.

Mr. Barker began to research automated tools to speed the back-spotfacing process. He tried one product that saved operators from having to re-attach cutting heads for every hole by projecting the cutting blade when the spindle was reversed. However, material tended to build up around the blade while cutting, blocking its ability to properly retract. This proved to be a problem while back-spotfacing a $10,000 aluminum casting. In this case, an operator was cutting 0.656-inch holes with 1.410-inch counterbores. The material built up, as usual, blocking the blade from retracting and thus damaging the bore. The whole casting had to be scrapped.

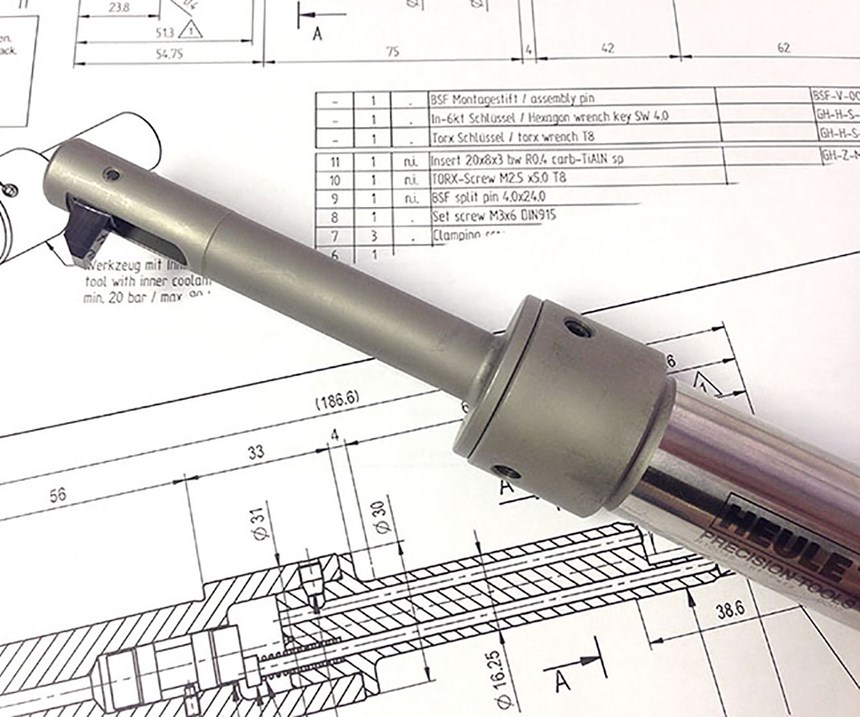

While looking for other alternatives, Mr. Barker came across Heule Tool’s back spotfacer (BSF) in a metalworking catalog. Using information from Heule’s website and technical engineers, he determined which of the 36 carbide tools in the series would suit Sicom’s needs.

The BSF’s boring blade retracts using coolant pressure independent of spindle direction or contact mechanism. When the spindle is deactivated, the coolant pressure moves a piston, forcing the blade back into the housing. The tool also has coolant pipes that continuously flush the blade window and the blade itself, preventing material buildup and removing metal chips and fragments from the blade housing. This meant no more damaging high-value castings because the blade would not reliably retract.

The BSF enables the team to back spotface a part without turning it over, saving time. Essentially a backward counterboring tool, the BSF is designed to machine spot faces ranging to 2.3 times the diameter of the through-hole. It can also counterbore without turning the work over. The machining is done on the backside of the drilled hole, and the part can stay on the production line without being re-angled.

The ability to keep the part on the production line—facilitated by reliable, coolant-enabled blade retraction—has saved the company an average of two to three hours of work per casting, by Mr. Barker’s estimates. His operators can focus on other machines, increasing the margin on each casting and effectively cutting days off of a standard turnaround. “It has automated a process for me that was very labor-intensive,” he says. “It has freed up operator time because I know when I get past a certain feature, it is lights-out machining.”

RELATED CONTENT

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

-

Drill And Bore With A Face Mill

Cutting holes by interpolating a face milling cutter may be a better process choice for many rough and even finish boring operations. Software improvements and better cutter designs allow expanding use of the versatile face mill for hole making.

-

Start With The Right Speeds And Feeds

Running rotary milling cutters at the proper speeds and feeds is critical to obtaining long tool life and superior results, and a good place to start is with the manufacturer's recommendations. These formulas and tips provide useful guidelines.

(1).1676494398075.png)