Starrag Five-Axis HMC Joins AMRC's Factory of the Future

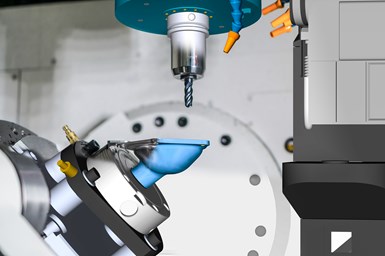

Starrag Heckert’s X40 joins a series of other multi-axis Starrag-supplied machines at the University of Sheffield Advanced Manufacturing Research Centre’s Factory of the Future.

A Starrag Heckert five-axis horizontal machining center (HMC) has joined a series of other multi-axis Starrag-supplied machines at the University of Sheffield Advanced Manufacturing Research Centre (AMRC) Factory of the Future.

Established in 2008, the Factory of the Future houses an array of manufacturing equipment to enable partner companies and project sponsors to develop and trial new technologies and processes.

In the Factory of the Future, the Heckert X40 now complements Starrag STC 1250 and Ecospeed machining centers, as well as a multi-axis Bumotec S191 turn-mill/machining center and NB251 high-speed blisk machining center.

Phil Kirkland, head of the machining group at the AMRC, says, “Our partnership with Starrag has been built over a number of years and this addition to the Factory of the Future portfolio further cements this; we expect the strengths of the Heckert X40 to be utilized to the full. Forthcoming projects for the machine will no doubt illustrate how a wide range of components can be produced effectively and efficiently, and the X40 technology will also enable our operators and engineers to continually upskill.”

The CNC features Starrag’s human-machine interface (HMI) for intuitive programming and operation. It also features x-, y- and z-axes travels of 700 mm × 750 mm × 750 mm plus workpiece heights of 500 mm, rapids of 80 m/min and a 30,000 revs/min spindle offering torque values of up to 350 Nm.

RELATED CONTENT

-

Don’t Forget The Drawbar

The force that holds the toolholder in the machining center's spindle can weaken over time. If you haven't checked drawbar force in a while, this may be the weak link in your process.

-

Maximum Aluminum: Optimizing Metal Removal Rate in Aluminum with a High Speed Spindle

Speed changes the rules. To maximize metal removal rate with a high speed spindle, follow some fundamental tooling considerations and mill at just the right rpm.

-

Composites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

%20(1).1676494398075.png)