Why Go Five-Axis: Machine Types and Benefits

Even as the benefits of five-axis machining stack up year by year, the barrier for entry crumbles.

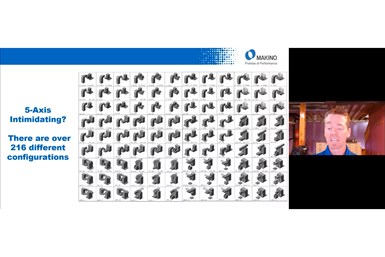

In a recent webinar, Makino senior application engineer Matt Nyer led viewers through a wealth of information and a series of examples as to what five-axis machines are on offer today, and why he believes these machines make five-axis simpler to use than ever before.

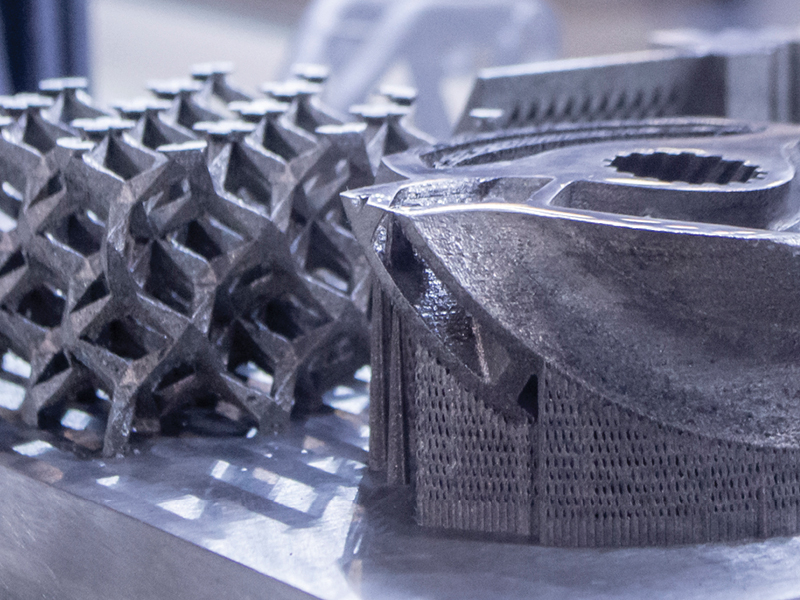

Matt Nyer illustrated a small portion of the different five-axis kinematic configurations available on the market. Photo Credit: Makino

What’s on the Market?

Over 216 different configurations of five-axis machines are on the market. For first-time users intimidated by so many options, Nyer recommends considering a smaller, curated list of machines.

Featured Content

Table/table configurations are quite common. Configurations with a horizontal or vertical trunnion move fastest — helpful, as speed can be a limiting factor in this type of machining — and offer relatively large work envelopes, expansive rotary travels and increased rigidity compared to other configurations. The accuracy of this configuration declines with increasing workpiece weight and size, and Nyer says the direct drives emit problematic levels of heat.

Slant structure table/table configurations keep the workpiece close to the center of rotation for maximum accuracy, but have rotary axis limits. Knuckle configurations improve access to the workpiece and offer the benefits of horizontal machining, but do not support the workpiece to the same extent as other configurations.

Lastly, third-party add-ons can act as table/table configurations. These offer excellent flexibility and relatively low cost, taking the form of a three-axis machine with a trunnion table or a four-axis horizontal with an extra axis on the pallet — Nyer was particularly fond of this type — but accuracy and speed are often problems. These add-ons can also shrink work envelopes, could introduce cables into the work area, and may not be fully compatible with some controls.

Head/head configurations differ from table/table configurations in that they rely entirely on tool rotation for their extra axes. This means that large workpieces have no bearing on accuracy, and operations can use shorter tools to add flexibility. However, Nyer said rigidity depends heavily on the design of the head, and cycle times suffer with lots of rotary axis movement.

Finally, mixed head/table configurations split up the rotaries, with one attached to the table and the other to the tool . They offer better accuracy and faster motion compared to fully tool-side setups. Although machines are generally smaller, the kinematics of this arrangement lend themselves well to large work envelopes. They generally move faster than comparably sized trunnion machines, Nyer cautioned users to take care to coordinate head and table movement.

These kinematic types can be employed for both 3+2 and five-axis machining. Three-axis machining is less expensive than either, but offers longer cycle times and a limited selection of large tools. Add-on style 3+2 machines add expense from the extra table and do not offer a continuous toolpath, but offer extremely simple coding — only four G-code lines added to a three-axis program — and a shorter tool. Full five-axis machining offers both short tools and full control over the contact point, but at higher prices.

General Five-Axis Questions

Nyer also addressed some frequently asked questions about five-axis machining. As a general rule, he noted that classifying the accuracy of five-axis is difficult because there are so many circumstances (and configurations) that play a role in the machines’ ultimate accuracy. Maintaining the center of rotation is especially important for proper accuracy, however, and Nyer said that many machines include or have support for part probing to establish or periodically update the parameters necessary to conduct successful five-axis machining.

Additionally, Nyer said engineering support can help determine best practices for setup, tooling, workholding, troubleshooting and more. Some machines also offer safety options, with collision safeguards standing out as particularly important.

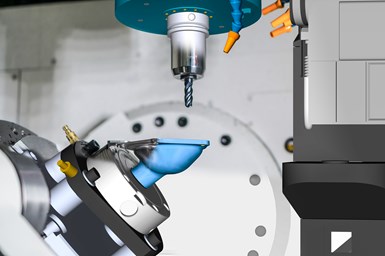

Nyer said a prismatic part like this requires 3+2 machining at the minimum to be feasible, joking, “if this hits my desk and I don’t have a five-axis machine, I’ll put in for vacation, maybe permanently.” Photo credit: Makino

What’s the Benefit?

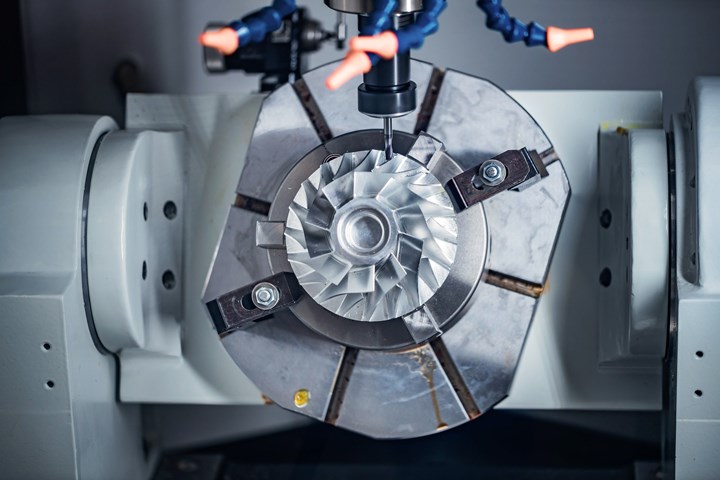

Five-axis machining improves cycle times and precision by enabling work on multiple surfaces within the same setup.

The flexibility granted by multiple approach angles opens up opportunities for shorter tools. Getting close to the workpiece can improve machining accuracy, surface quality, metal removal rates and cutting speeds. Tools can also use standard shapes for tapered surfaces, eliminating the need for separate tooling. Improved part access not only makes keeping an eye on the part easier for operators, but also simplifies verification. Operators can use rotary motion to true fixtures.

Programming has also come a long way since the early days of five-axis machining. Modern CAD/CAM systems use five-axis programming that is similar to three-axis programming. Nyer said there is a small learning curve adjusting to the extra programming for the two new axes, but it is just that — small.

What To Watch For?

Troubleshooting can initially be more difficult for five-axis machining, Nyer said, but the increased flexibility of five-axis machining means adjusting toolpaths to avoid problems is much simpler.

Coolant drainage and foaming still depends on the machine design and the chemical formation of the coolant. Nyer recommended asking tooling distributors for more specifics about whether a particular coolant will prove suited to a particular machine.

Toolpath simulation can also prove to be a great boon to five-axis machining. Nyers is a self-described “big fan of offline simulation,” and said it improves machine prove-out time.

RELATED CONTENT

-

Rolling Threads Has Advantages

With macros and canned cycles resident in the CNC on most contemporary turning centers, single point turning of OD threads can seem like almost a default process decision. However, for numerous applications, OD thread rolling has inherent advantages as an alternative to cutting threads.

-

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

-

Centerless Grinding: Not Magic!

Achieving consistent and quality results from the centerless grinding process requires an understanding of the basic fundamentals. Most application problems associated with centerless grinding derive from a misunderstanding of the basics. This article explains why the centerless process works and how to use it most effectively in your shop.

%20(1).1676494398075.png)