Weldon Solutions Complements its Grinders With Automation

Weldon Solutions’ candy-picking robot is ready and waiting to distribute over 4,000 pieces of candy this year in the company’s booth.

#imts

Weldon Solutions’ candy-picking robot is ready and waiting to distribute over 4,000 pieces of candy this year in the company’s booth. The crowd favorite demonstration isn’t just for fun; it showcases the varied automation capabilities Weldon offers in addition to its CNC grinding machines.

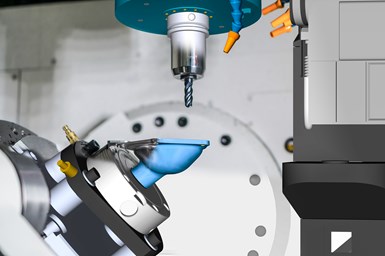

The AGN4 from Weldon will be on display with optional automation installed.

Photo Credit: Weldon

Weldon has designed a portfolio of grinding machines that meet the needs of various industries. The company found that its offerings enable its customers to find a machine that fits their needs – rather than buying something too big or too small. The company’s offerings are further customizable through bed extensions and automation.

This year, the company showcases its G300 OD grinder. This new offering, developed in cooperation with Tsugami, is another example of how the company saw a need for a mid-sized grinder on the market. Weldon’s customized, imported machine features an 8.4” FANUC Series 0i-TD control with a battery backup absolute feedback system. The 300-mm swing and 500-mm distance between centers (upgradeable to 1000 mm) can drive a 330-lb workpiece with its 10-hp wheelhead.

The company has live demonstrations of its automation capabilities with various arms and loading devices.

The International Manufacturing Technology Show runs September 12 - 17, 2022 at McCormick Place in Chicago. Register for IMTS today to start planning your show.

RELATED CONTENT

-

Use the SMART Criteria to Develop Your Company's Goals

Be SMART, and use these five characteristics to improve your company.

-

Energy Saving Factory Automation Equipment and the Environment

The application of energy efficient motor systems can greatly reduce the overall environmental impact and cost to operate this equipment. Advancements in electric motor design and the associated drive system in modern automation equipment can be extremely energy efficient. Much of the time the most energy efficient machine will also have the highest performance but there is normally an upfront cost associated with the performance and efficiency. That added cost related with selecting energy efficient equipment may be easily returned as lowered energy costs, high performance and reliability.

-

Machining, Disruption and the Years Ahead

Three major technological advancements have changed modern manufacturing. Pay attention or get left behind.

%20(1).1676494398075.png)