MC Machinery's Sinker EDMs Feature AI Adaptive Control

The artificial intelligence adaptive control technology is said to help optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

Edited by Angela Osborne

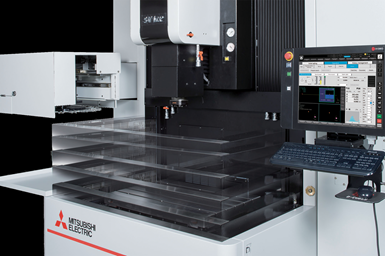

Photo Credit: MC Machinery

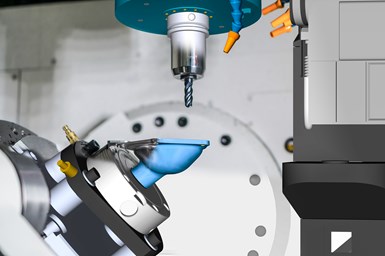

MC Machinery’s latest EDM and precision milling technology includes wire and sinker EDMs, machining centers and automation. The company, a subsidiary of the Mitsubishi Corporation, is a supplier and servicer of fabrication and milling equipment, including Mitsubishi lasers, EDMs and automation systems.

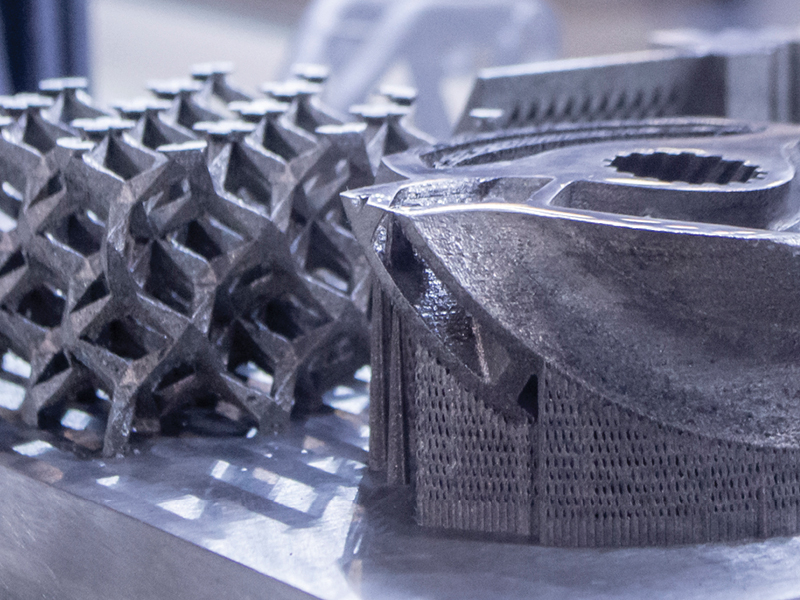

The new Sinker EDMs feature artificial intelligence (AI) adaptive control technology. The company says the Mitsubishi SV12P and SG12 sinker EDMs optimize performance, improve productivity, reduce electrical consumption and take the guesswork out of estimating machining time.

The AI technology is said to make logical use of condition-monitoring data. For example, these new machines can diagnose real-time problems within the burn and directly modify specific parameters for a stable and accurate output. This enables machine operators of all experience levels to produce quality results in complex cavities and shapes.

Because the AI technology analyzes current sensor data to determine optimal conditions, it reduces overall electrode wear and costs. According to the company, by monitoring these parameters, the machine operates more efficiently and can more accurately predict machining times.

The International Manufacturing Technology Show runs September 12 - 17, 2022 at McCormick Place in Chicago. Register for IMTS today to start planning your show.

RELATED CONTENT

-

The Hidden Cost Of EDM Wire Consumption

Excessive wire consumption on a wire electrical discharge machine is costly. Technology that allows slower unspooling speeds without compromising results appears to be the answer.

-

Trends In EDM

Electrical discharge machines, both wire and ram type, have undergone rapid improvements in capability, economical operation, speed and flexibility. New applications are continually emerging as shops discover the advantages of this process.

-

EDMing Beryllium Copper: An Introduction

Beryllium copper offers many benefts to the moldmaker and plastic injection molder, yet questions remain on how to best EDM it, which alloy to specify, where to use it, and is it safe to work with?

%20(1).1676494398075.png)