Rapid Metal Parts Removal With EDM Network Inc.'s New EDM

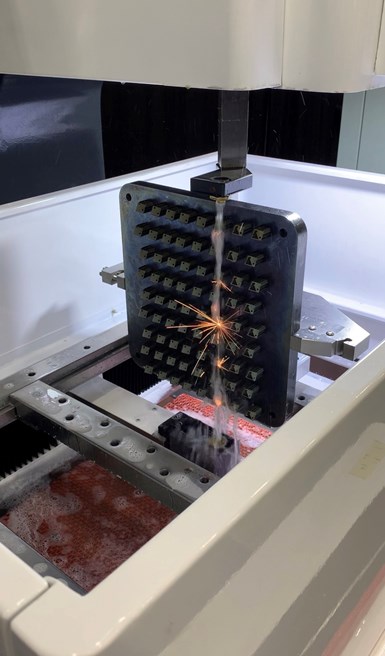

According to EDM Network Inc., the Fast Wire EDM is capable of cutting speeds that are two to three times faster than traditional wire EDMs.

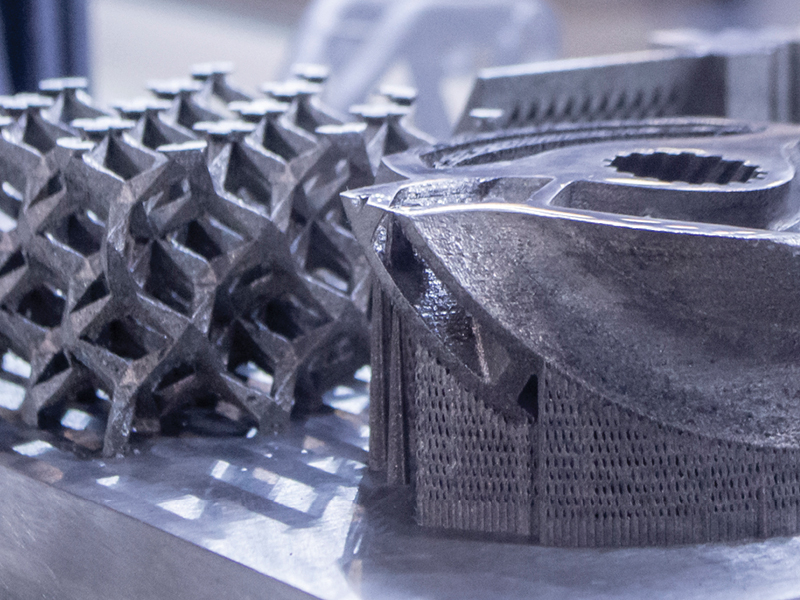

EDM Network Inc. introduced its new Fast Wire EDM at AM2021 in Cincinnati, Ohio. The Fast Wire EDM was developed to rapidly remove 3D printed metal parts from the build plate by using a small .007" diameter molybdenum wire cutting a .008" wide kerf. This narrow kerf enables the EDM to cut about .010" away from the build plate, which reduces the cost of the additional support material needed by traditional saws.

According to EDM Network Inc., its Fast Wire EDMs are different from traditional brass wire EDMs because they are not flush dependent and do not need auxiliary flush lines or submerged cutting. In the interrupted cuts on a tall build plate, the Fast Wire EDMs will not break the wire because the molybdenum wire has very high tensile strength, and the water additive that is used causes the water to adhere to the fast moving wire, enabling the water to pull the swarf (chips) out of the cut zone. Cut speeds of two to three times faster than traditional wire EDMs are reportedly achievable.

In addition, the wire path can be programmed to follow the support structure and remove support material in the cut off process – rather than taking a straight cut along the face of the build plate – which saves time on the secondary machining process.

The Fast Wire EDMs are available in three models to handle build plates of 410 mm, 625 mm and 1050 mm high.

RELATED CONTENT

-

Use Your Machinists to Make Dies

By systemizing die making into repeatable steps, Dies Plus, a division of Otto Engineering, is using its machinists to effectively make dies. This solution relies on a paperless color-coding system to convey the tolerances machinists need to hit in order for tool and die makers to do the final fitting.

-

The Hidden Cost Of EDM Wire Consumption

Excessive wire consumption on a wire electrical discharge machine is costly. Technology that allows slower unspooling speeds without compromising results appears to be the answer.

-

Wire EDM In The Extreme

Cutting metal with an energized strand of wire is still one of the most dynamic frontiers in metalworking, and this shop goes to extremes to keep up with the latest advances. It has even developed some of its own.

%20(1).1676494398075.png)