Automation Cell Outperforms CNC Machines Fourfold

An automated turnkey machining cell simplified one Utahan manufacturer’s part handling and halved its cycle times.

3rd Gen Machine deviated from traditional turnkey setups of the JobShop Cell by requesting the chance to adapt its existing programs to the automation cell, rather than rely on Methods Machine Tool to program 3rd Gen’s parts. The shop also asked for the capability to swap between part programs with a single value input on the teach pendant.

Evan Jones founded 3rd Gen Machine in 2007, with one customer, a handful of employees and a few hand-me-down machines from his father’s mom-and-pop shop.

Recently, however, 3rd Gen Machine’s tried-and-true process started proving not-so-true. Chip imprint scratches created too much scrap and manual machine loading swallowed too much time.

Featured Content

“That day, we sent a purchase order to Methods for the automation system,” Jones says.

Time for Turnkey

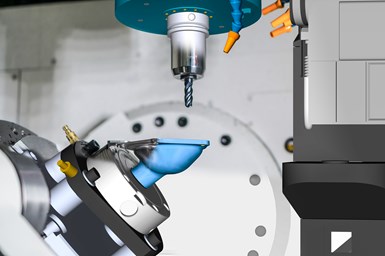

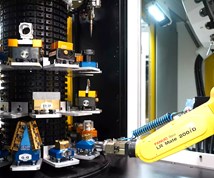

Jones is referring to Methods Machine Tools’ JobShop Cell, which includes two FANUC RoboDrills and an articulating FANUC LR Mate 200iD robot. The RoboDrills are short-bed, vertical machines, and the whole cell occupies only slightly more floor space than one of Jones’ existing HMCs. For 3rd Gen Machine’s first JobShop Cell, Jones asked Methods to program a function into the robot’s teach pendant that would enable switching between part programs

The JobShop Cell ended up being four times as productive as any of 3rd Gen Machine’s other machining centers.

Originally, Methods estimated a cycle time of 1 to 2 minutes for a simple part, with another 15 to 20 seconds for part changes. Jones had been impressed with this estimation, which would have been down from an average of two minutes for the same part using the shop’s HMCs

The JobShop Cell also enabled lights-out machining — or, as close to it as an already 24-hour operation can get. 3rd Gen Machine’s machinists run multiple machines simultaneously, so the automation cell’s ability to run unattended for hours at a time eases the strain on the machinists even as it improves the shop’s productivity.

3rd Gen Machine owner Evan Jones compares learning new technology to a “man versus machine” battle that requires adapting to evolving circumstances. In this case, the JobShop Cells were so productive that spacial bottlenecks required staging other machines’ finished parts in shipping containers.

Chip Maintenance

Adopting the JobShop Cells wasn’t completely free of adjustments, however. Jones found that chips coming off the parts in the RoboDrills could land on the robot’s sensors, making the robot think it was engaged with a part instead of performing offline prep work.

3rd Gen Machine engineered some components

Programming the Future

Methods may have performed the initial set up for the FANUC LR Mate 200iD in 3rd Gen Machine’s JobShop Cell, but the shop is not content to rest there. 3rd Gen Machine programs its parts into the JobShop Cells, and actively works to improve them — as demonstrated by the 25% optimization in cycle times for simple parts mentioned earlier. Moreover, Jones and a few of his machinists are taking robotics programming courses to fine-tune the robot and prove the Cell as they see fit.

The extra productivity of these machines has made 3rd Gen Machine a tidy profit, and Jones is using that capacity to expand with a new building. Until the building is finished, however, 3rd Gen’s largest problem might be that the JobShop Cell is too productive — the company has needed to purchase shipping containers so it has the space to stage finished goods from its other machines.

RELATED CONTENT

-

Understanding Jerk Control

What does "jerk" refer to, and where does it fit into machine performance?

-

The 400° Difference

Cryogenic machining achieves dramatic tool life gains not by flooding the cut, but by refrigerating the tool.

-

Drilling Deep Holes On A VMC

The recipe for best results is simple: Start with a rigid machine, add a high pressure through-the-spindle coolant system, then combine these with the right drill geometry plus the right speeds and feeds.

%20(1).1676494398075.png)