Top Shops 2011: Bob’s Design Engineering Inc.

B.D.E’s CAD/CAM experience helps speed customers’ products to market.

#topshops

Our “Top Shops” benchmarking survey asked this question: What one strategy or technology has had the biggest influence on your success? Overall, the most striking characteristic of the responses is their diversity. Although it is significant that several technologies and strategies emerged, there was no clear winner or broad consensus indicated by the results.

However, several respondents pointed to CAD/CAM software as the technology having the biggest influence. In fact, most of these comments named the specific software product that made a difference. This is perhaps an indication of how important design capability or specific programming features from a given developer are in a shop’s perception of its success factors.

Featured Content

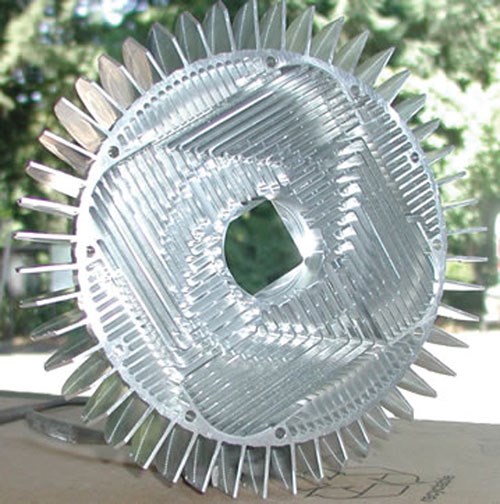

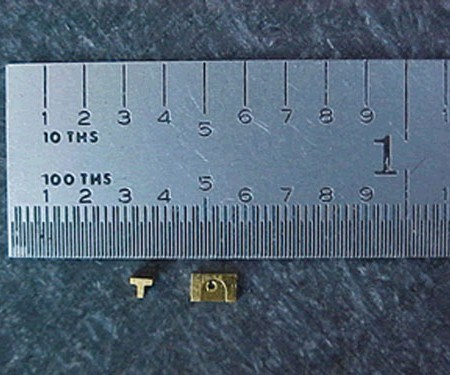

Bob’s Design Engineering (B.D.E.) is one example of a shop leveraging CAD/CAM technology. It uses its software expertise to help customers in the electrical, energy and medical industries shrink their new-product development cycles. The shop provides valued CAD/CAM consulting, design, prototyping, and research and development services. It is especially skilled at providing product engineering specifically for industrial printers, cameras and transformer-monitoring devices.

When working with customers in the early stages of a new project, the shop can create CAD drawings and mock-ups as well as perform 3D modeling. For projects at other stages of development, it offers computer-aided manufacturing services and materials selection advice.

B.D.E. can work with a variety of design software platforms, including Autocad, Inventor, Ironcad, Pro/Engineer and Solidworks. For component machining, the shop uses Mastercam software from CNC Solutions to create part programs and has had success using the VoluMill toolpath engine from Celeritive Technologies.

While B.D.E has a wealth of machining capabilities, including milling, turning and EDM, it is able to diversify itself from other shops by providing a variety of product design and process engineering services to its customers. In fact, calling companies such as B.D.E. a “shop” is almost a disservice. That’s because they can provide much more than parts machined on time and to specification.

Company Background

B.D.E. is a medium-sized manufacturer that combines old-world craftsmanship with state-of-the-art technology to provide innovative solutions to its customers’ manufacturing needs. Its staff averages more than 25 years of experience in the machining and tool-making disciplines. With CAD/CAM and modern CNC milling, turning and EDM capabilities, its staff provides excellent service in meeting its customers’ requirements for fast part development, manufacture and delivery.

Bob Hale, B.D.E. founder, has a strong “can do” philosophy and has infused this throughout the company. By bringing all parties together to focus on solutions, B.D.E. has built a strong reputation for helping customers solve their manufacturing problems. This philosophy is the driving force behind the constant evaluation and implementation of new technologies. Its employees continually push the envelope for better and faster methods. As a result, B.D.E. has developed manufacturing capabilities that are strong and diverse. Its staff designs and builds all types of tooling, fixtures and prototypes and can perform short-run production and just about anything else that requires precision craftsmanship.

Key Personnel

- Bob Hale, President/Owner

- Claudia Hale, President/Owner

- Rick Hale, Vice President

Products/Services

End Markets Served

- Electronics

- Energy

- Medical

Workpiece Materials Commonly Machined

- Alloy Steels

- Aluminum

- Beryllium

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Magnesium

- Molybdenum

- Nickel

- Stainless Steel

- Titanium

- Tungsten

RELATED CONTENT

-

Machining with the Environment in Mind

It’s safe to assume that most shops recognize the importance of being environmentally responsible. However, benchmarking data suggests that the effort shops put into both recycling and reducing energy consumption varies.

-

See How You Stack Up

“Top Shops” benchmarking data sheds light on what it takes to be one of the nation’s leading machining businesses.

-

Best Practices of Top U.S. Shops

Results from our fifth annual Top Shops benchmarking survey reveal operational metrics, strategies and tools common to leading machine shops here in the States.

.jpg;width=70;height=70;mode=crop)

(1).1676494398075.png)