What can a company expect that adopts additive manufacturing (AM) as a means of part production — particularly an established manufacturer succeeding in machining? While additive offers considerable promise in terms of design freedoms, assembly consolidation and production without any need for hard-tooled processes, realizing this promise by getting to a repeatable, cost-effective production via AM can entail both process engineering challenges and culture changes. The way forward can be an uphill battle.

To gain enough traction to make this ascent, companies need to set realistic expectations for AM adoption and seek out little wins — and key learnings –– along the way. As these little wins begin to accumulate, the company gains momentum to help reach escape velocity. This climb is fueled by finding and creating value with AM across the entire organization, not just going for it all with the topology optimized, bio-inspired, latticed AM part from the start. Much lower hanging fruit exists that can help build confidence and reduce risk along the way.

Featured Content

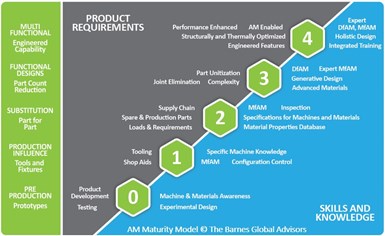

Maturity models like this one from The Barnes Global Advisors delineate five levels that help companies progress their AM skills and knowledge as they begin to adopt AM.

Photo Credit: The Barnes Global Advisors

One of the more useful aids that I have seen for this discussion is the AM Maturity Model that John Barnes sketched on the back of a napkin when he began The Barnes Global Advisors five years ago (see image). The model has withstood the test of time, and I refer to it frequently in the AM training that I run with the team as their educational advisor. I find it useful not only because it provides guidance on ways to extract more value from AM, but also because it identifies what can be learned along the way — and this is what really makes AM stick.

As shown in the figure, the maturity model begins at Level 0 with pre-production, which includes design prototypes, visual aids and test fixtures. In today’s industry, this level of use is “table stakes” for AM, which is why it is Level 0, not 1. In other words, if your company is not already doing this, then you are already behind. This technology has been around for over 30 years, and entry-level desktop systems are as low as $200. So, not only are you behind, but your knowledge about the different AM processes and the material and process tradeoffs is lacking, giving you fewer handholds to start your ascent.

Level 1 includes things that influence production, such as fixtures, tooling and other shop aids. 3D-printed sand molds would fit into this category as would short-run tools. This level is easy to reach, but often overlooked because it is not considered a sexy or cool use of AM. As a result, you lose an opportunity to gain deeper knowledge and insight into the different AM technologies in a low-risk setting. You also miss an opportunity to start thinking creatively about how you approach design, in this case, of fixtures and shop aids, not parts.

Level 2 is the most difficult level on the climb, namely, part-for-part replacement with AM. The challenges of AM process substitution are well-known, but this is still where most companies new to AM try to start their climb. Luckily, supply chain disruptions are reshaping the landscape enough that AM is finding wins in maintenance, repair and operations (MRO) and sustainment due to the long delays many companies are now facing. While painful, attaining this level helps companies understand specification, geometric dimensioning and tolerancing (GD&T) and inspection of AM parts to ensure requirements are being met. It’s here, too, that designers get a chance to apply design for AM (DfAM) by modifying parts to save cost, for example.

Level 3 is where the fun begins as the peak starts to come into view. Here, design engineers and manufacturing engineers can find creative ways to eliminate joins, reduce part count and unitize assemblies while learning how to substitute materials for enhanced part performance. Prior to this level, designers did not have the freedom to make significant changes to the part geometry or material; therefore, they were constrained by what they could do by varying build orientation or support structures, for example — none of which add value to a part, only save cost.

Companies that reach Level 3 on their climb recognize that AM benefits can only be achieved when AM’s limitations are addressed during the design process, much like designing for any other manufacturing process. Only after this realization is made can they climb to Level 4, which leads to the much heralded “plateau of productivity.” This is where world-class DfAM knowledge leads to AM-optimized parts with features that can only made with AM. Multimaterial AM processes may come into view now as well, as you reflect on your climb and see many other paths you could climb as you consider different AM processes and opportunities.

As they say, the view is always better from the top.

RELATED CONTENT

-

EDMs Spark Interest

MC Machinery is showing off its suite of EDMs and milling machines designed for die/mold applications.

-

Cylindrical Grinder Takes on Complex ID Operations

One of the centerpieces of United Grinding’s booth at IMTS is a grinding machine designed for ID grinding of hard materials.

-

Inside of JRLON Working With Metal, Plastic and Rubber

Jrlon, Inc. is recognized as a dependable source and leading supplier of plastic and specialty metal products. They are one of the premier PTFE processors in the United States. Jrlon's expertise also covers a wide range of other performance plastic materials and alloy steels for custom molding, machining, gear manufacturing, technical industrial coatings, welding, and sheet metal fabrication. Driven by innovative designers and engineers, Jrlon manufactures unique products vital to a wide variety of industries.

(1).1676494398075.png)