“[I]f you think of dropping a leaf in a stream, sometimes it's going to rocket down that stream if it's in the right path, and it's going to go really fast. Other times, it may get swallowed up in the vortex over on the side somewhere,” says Ashley Eckhoff, additive manufacturing program team member at Siemens Digital Industries Software.

When it comes to fluid flow, a designer’s instinct might be to create plenty of space, to lay out a wide “stream” for the hypothetical “leaf” to travel through. But a wide-open space isn’t necessarily conducive to efficient fluid flow, Eckhoff says. Too much space creates more opportunities for those vortexes to form, causing the fluid to double back on itself and waste energy.

Featured Content

But until the advent of simulation software, designers had no real way of seeing this. Many of the “streams” in the physical world are actually too large, too inefficient and require more power to operate than necessary as a result. For an example, look no further than the so-called “Mighty Duct.”

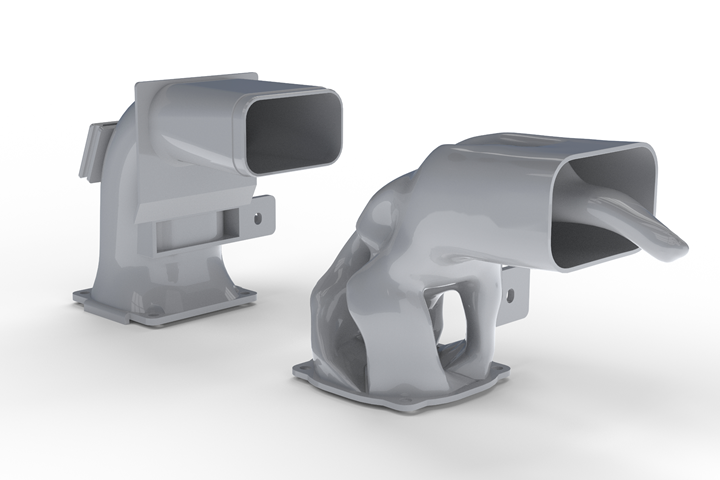

Nicknamed the “Mighty Duct,” the component to the right is a new version of an air duct for the Multi Jet Fusion (MJF) 3D printing platform that was redesigned using computational fluid dynamics. Both this duct and its previous version (left) are 3D printed using MJF. Images: Siemens

This air duct is a component for HP’s Multi Jet Fusion (MJF) polymer 3D printer. The nylon part is a piece of the ductwork that delivers air to the printhead, keeping it cool during operation. Until recently, this air duct had a fairly conventional shape derived from an earlier design intended for injection molding.

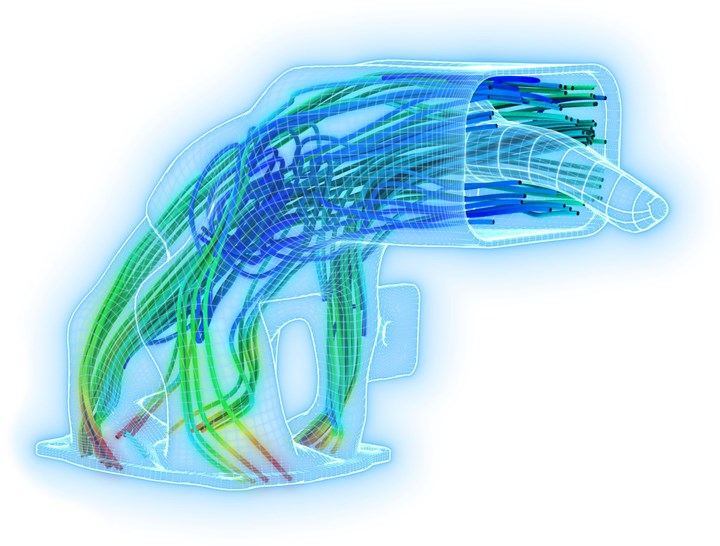

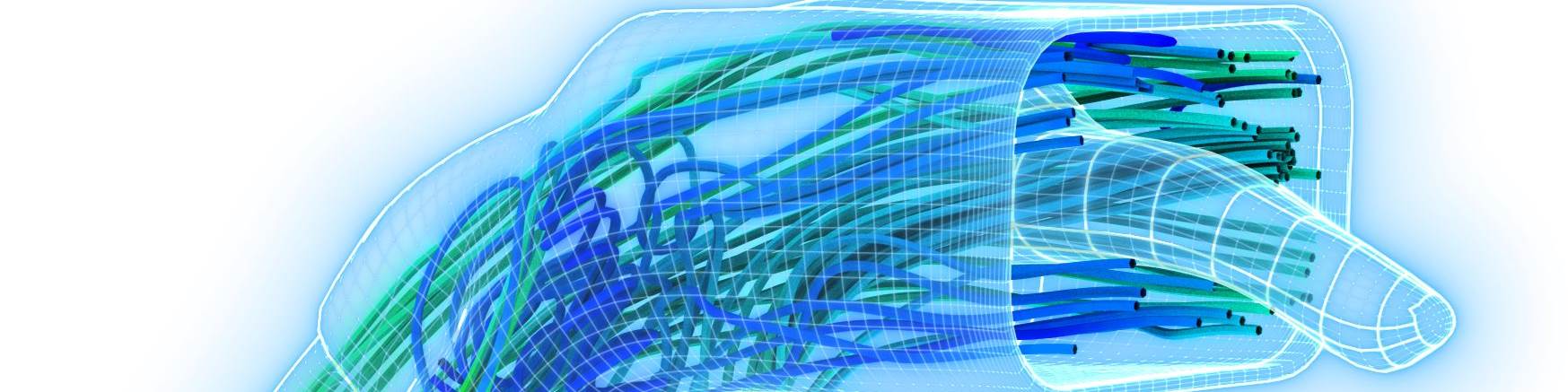

But when HP teamed up with Siemens, collaborators saw this air duct as a design opportunity. Simulating the airflow through Siemens’ Star CCM+ computational fluid dynamics software revealed that the air wasn’t utilizing all the space allotted in the original design; rather, it followed four distinct pathways through the duct’s main turn.

Computational fluid dynamics (CFD) software from Siemens revealed that the air wasn’t utilizing all the space inside the original duct design. A new, 3D printable version eliminates the unused space and funnels air through the four most efficient pathways instead.

Eckhoff and his team used the CFD data as the basis for a new design, one that eliminates wasted space and instead directs the volume of air through the pathways it naturally wants to follow. The resulting air duct is unlike any previous, human-driven design and would be impossible to manufacture without 3D printing. Its complexity delivers significant performance advantages — HP reports that the new design delivers a 22% improvement in efficiency. While the rest of the cooling system remains the same for now, efficiency gains like those delivered by the Mighty Duct could lead to other improvements in the future, like a smaller fan and reduced energy needed to move air through the system.

Air flow efficiency wasn’t the only win from this project, however. Peter Zelinski and I sat down with Eckhoff and Luis Baldez, head of strategic initiatives at HP, in a recent episode of The Cool Parts Show to learn how the Mighty Duct also showcases assembly consolidation, rapid design iteration, reduced manufacturing lead times and more. The episode was originally broadcast live through the IMTS spark platform; view an edited version here:

For more 3D printing wins, find additional episodes at TheCoolPartsShow.com. Have a neat 3D printed part to share? Consider entering The Cool Parts Showcase!

RELATED CONTENT

-

Machining, Disruption and the Years Ahead

Three major technological advancements have changed modern manufacturing. Pay attention or get left behind.

-

Real Examples of 3D Printing in the Automotive Industry

3D printed end-use parts are going onto vehicles with increasing frequency. Recent real-world examples showcase additive manufacturing benefits in design, weight savings and more.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

.jpg;width=70;height=70;mode=crop)

(1).1676494398075.png)