Can Transparency Bring More Efficient Sourcing?

A resource that aims to be free for machine shops asks detailed capability information so parts can be matched to producers, and OEMs can target RFQs to shops that are ready to run the work.

#zaxis

It is not hard for an OEM in need of machined parts with specific requirements to find a machine shop able to meet the need. The problem lies in also finding so many other shops at the same time that are not quite suited to the work. How does the buyer identify which of the shops that seem promising is actually a good fit?

And it is not hard for that same buyer seeking machining work to find shops with open capacity, even open capacity for particular machine types and travels. The problem is that capacity is not a commodity. Different shops use their capacities in different ways.

Featured Content

All of this is as much a problem for machine shops as it is for buyers of machining services. The overabundance of RFQs that shops contend with and sort through is in part a result of the lack of transparency, and the lack of knowledge, between manufacturing buyers and providers. Ironically, shops would be aided by a platform that would accurately characterize and filter them, and therefore in many cases accurately exclude them from consideration.

A group of supply-chain professionals formerly with SpaceX is now working to develop exactly this platform. Their company is Datum, and the platform they aim to commercialize is based on “radical transparency” into supplier capabilities, says CEO Robert Pakalski. I recently spoke with him about the company, its aims and what role it might play in buyer/supplier relationships of the future.

Significantly, he says only half of Datum is supply-chain experts. The startup’s staff of 10 at the moment I spoke with him included five from the supply-chain world and five with software expertise. The problems supply-chain leaders encounter are in some cases solvable using data the part file contains, he notes, if only the data can be effectively leveraged. The logic-based sourcing platform Datum is building interrogates

“Machine shops are not apples to apples,” Pakalski says. To be sure, they differ in far more than their machine types and capacities, but even these differences are opaque to OEMs, who themselves might be sourcing parts through purchasing professionals who don’t necessarily discern the different machining needs of different parts. Examples of the kinds of routine mismatches that result include RFQs for five-axis jobs being sent to three-axis shops, and large parts left hanging off the machine bed because the job was won by a shop with not quite the right work envelope size. And this says nothing of the complex part that cannot be machined efficiently by a given shop because it lacks a multitasking turning machine with the right Y-axis travel.

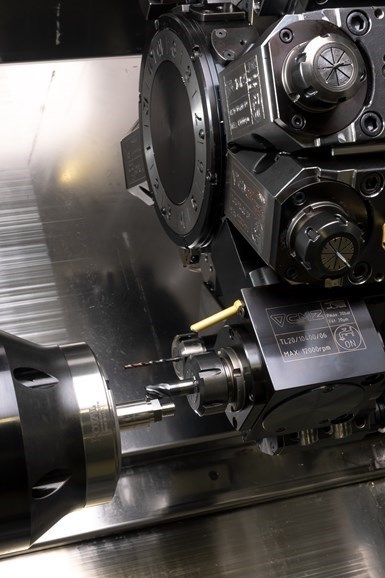

The work envelope of multitasking machines is an example of a capability metric useful for prequalifying shops. (This photo from Prosper-Tech Machine & Tool, which we wrote about here.)

On a multitasking machine, Pakalski notes there are fundamental characteristics important to qualify a given supplier to run a job. They include machine envelope in diameter and length; the various axes useful to the part and their travels; and the orientation of the spindle. From there, other machine parameters might prove valuable as additional qualification constraints. Meanwhile, other machine tool types have their own sets of important parameters. In characterizing machines, he says the team has focused on specifications apt to be germane to successfully machining parts needed by the space sector (the founders’ home field). Ultimately, interrogating the CAD file will allow for automatically identifying the machining process and the specific machine tool specs the part needs, including optional spec requirements added by the user, and Datum’s system will then be able to layer other considerations into the qualification such as a shop’s quality capabilities and its proximity to buyer.

It is a difficult analysis for software to perform automatically, but that is the aim. “We will start with space because we want to be able to nail one industry,” he says. The team will proceed industry by industry from there, and also proceed into other processes beyond CNC machining.

A test of 100 representative machined parts for the space sector so far shows Datum’s platform delivering 80% success at matching parts to correct shops. Further refinement can raise this to near 100%, the CEO says. When I spoke to him, there were 60 machining suppliers Datum had gathered into the platform that

Machine shops brought into the platform provide needed data about their machines and capabilities. They will also be able to freely flag and unflag their status as accepting work. Shops’ inclusion will be free of charge, Pakalski says, because Datum expects to profit by selling access to the manufacturing buyers, who need the assist in filtering and identifying suppliers. Once the buyer finds a promising supplier through the system, the buyer will communicate and contract with the shop directly.

“We won’t be a broker — we don’t want that role,” he says. Value will instead come from saving time for manufacturing buyers and delivering better manufacturing by more cleanly and accurately connecting parts to producers. OEMs will pay to employ the system, and to realize this value. For this reason, the Datum team expects shops will want to join and be discoverable there. In other words, Pakalski expects shops will want to be part of a network that is discerning and sensitive enough to sometimes rule them out.

RELATED CONTENT

-

A Quick Look At PEEK Machining

The use of PEEK polymer for medical implant devices is on the rise. A supplier of this material offers cutting tool tips for shops that may soon add PEEK machining to their list of capabilities.

-

10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

-

Tips for Tapping Titanium Alloys

Creating threaded holes in titanium alloys calls for proper techniques based on an understanding of both the properties of these materials and the peculiarities of the tapping process.

.jpg;width=70;height=70;mode=crop)

(1).1676494398075.png)