Stecker Machine Company is a mid- to high-volume machine shop specializing in aluminum and iron castings. Recently honored by Top Shops for its worker-focused processes, the shop also has multiple fully automated cells dedicated to its highest-volume parts. These parts, all with volumes in the tens of thousands, demonstrate how shops can use automation to add capacity rather than reduce personnel.

Stecker Machine has two buildings for machining parts. While both locations have numerous machining centers staffed by operators trained in-house, Plant 2 also has highly automated production lines for machining heavy truck and on-highway components. The production line shown above produces 90,000 finished parts every year.

Featured Content

This line includes four FANUC robotic arms and numerous conveyors that transport castings to stations for machining and deburring operations on a Doosan (now DN Solutions) vertical machining center and four Toyoda horizontal machining centers. After machining, parts are deburred, pressure tested and washed before workers transport them to shipping. This level of automation enables Stecker Machine to meet the high volume of parts needed with consistent quality.

These castings require four machining operations, plus finishing operations before they can be shipped off to customers. The machining operations include boring, drilling and threading, as well as cleaning up edges and finishing certain surfaces. This level of complexity is common for Stecker Machine, but to replicate it with an automated process took weeks of careful planning, according to Account and Customer Service Manager Scott Waak. Waak is part of a team that has been instrumental in the planning and implementation of the company’s recent automated cells.

Stecker produces heavy and medium duty part families, with the heavy duty requiring 60,000 parts year. For each version, the company has a separate automation cell producing tens of thousands of units every year.

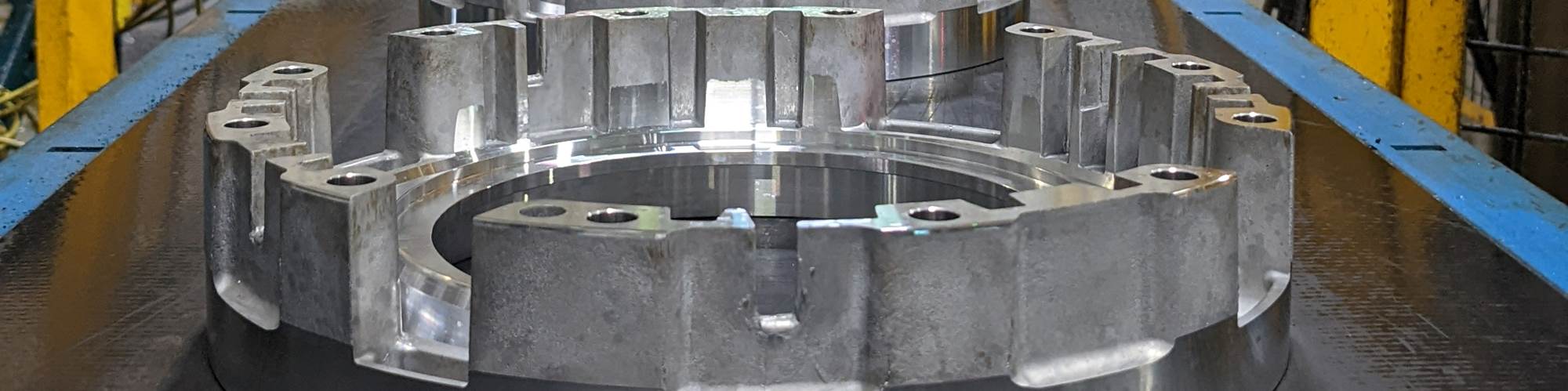

Another automated cell produces a mating set of circular transmission parts. In this cell the machines are arranged is a flattened “V” formation to fit the available floor space. Each arm of the “V” produces half the parts and a CMM station is at the center. Altogether, each half of this cell produces 120,000 parts every year, with one person per shift overseeing the cell.

Each branch of the “V” begins with a gantry-loaded Muratec MW200 two-spindle lathe that completes tight-tolerance turning operations on both sides of the part. A robot then moves the part to an HMC for final machining of critical features before taking it to a cleaning station. The left and right sides of the cell are identical. Either side can be set up to run either of the two parts in the product family.

A conveyor system carries finished parts out for each of the two production lines that are part of this automation cell. The two lines share a small inline CMM that inspects parts in real time from the twin lines to ensure that the company is maintaining tolerance.

According to Waak, Stecker Machine developed this production line to meet capacity while maintaining accuracy required for the part’s complex design. “A cell like this works because you’re increasing capacity beyond what you could do before,” he says. The company already knew how to produce medium-volume jobs successfully, as their Top Shop status demonstrates. These automated cells enable the company to pursue jobs they otherwise could not. “If you’re standing still, you’re going to get left behind.”

RELATED CONTENT

-

Bar Puller Basics

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. This article explains how they work and how shops can benefit from using them.

-

Use the SMART Criteria to Develop Your Company's Goals

Be SMART, and use these five characteristics to improve your company.

-

Sometimes the Trickiest Part of CNC Machining Is Holding the Part

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining cell.

(1).1676494398075.png)