Make the Most of Your Interactions With Salespeople

By: Udo Jahn

Don’t miss out on products and knowledge that could help your company.

#viewfrommyshop

There's Your Waste, Shaw! An Argument for Shop Reinvestment

By: Brent Donaldson

The fictional Don Walling had it right: Innovation and long-term success for machine shops requires investments in technology and people. Not just one, but both.

#thesetup

Metalworking Activity Crept Into Growth Mode in February

By: Jan Schafer

The GBI closed at 50.6 in February, calling for cautious optimism.

#economics

How Aneesa Muthana Found Her Own Path in Manufacturing

By: Nathaniel Fields

From working phones at 11 years old to reinventing her own business during a downturn, here's how Aneesa Muthana created her own path in manufacturing.

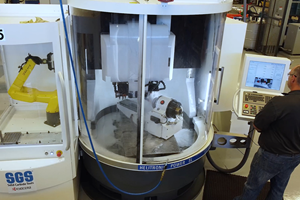

Rebuilding Machine Centers: Low Cost, Higher Performance

By: Evan Doran

By sending its grinding machines out for rebuilding, a tooling manufacturer achieved higher speeds at roughly three-fourths the cost of a new machine.

Handling the Growth of an Adaptable Automation System

By: Nathaniel Fields

Implementing an adaptable automation system helped this shop stay on top of seasonal swings in demand. To effectively grow this system, it had to keep several considerations in mind.

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

By: Peter Zelinski

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

#zaxis #Basics

3 Keys to Digital Marketing

By: Catherine Ross

Whether you’re an influencer who lives for likes or a novice marketer who swears “tick, tock” is the sound a clock makes, you can launch a successful digital marketing presence.

Metrology: Automation’s Unsung Hero

By: Chris Chidzik, AMT Principal Economist

When contemplating automation, it is easy to envision a robot moving material from point A to point B, parts coming out of a machine and being ferried by conveyors to the next step, or pallet changers reloading fresh stock back into a machine.

What are Harmonics in Milling?

By: Tony Schmitz

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

#Basics

MetalQuest - Robotic Automation of a Machine Shop

Robots have helped MetalQuest stay competitive and deal with the skills gap. See how they have integrated high-level automation into all aspects of their shop.

#videoVFMS

How to Pass the Job Interview as an Employer

By: Udo Jahn

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

#Basics #successionplanning #workforcedevelopment

How to Optimize Operator Efficiency on Any Shop Floor

By: John Miller

Striking the perfect balance of person to machine is unique to each shop and can depend on a number of factors, including the type of work a shop undertakes, the available equipment, staffing levels, scheduling and more.

#Basics

ESOP Solidifies Culture of Continuous Improvement

By: Evan Doran

Astro Machine Works’ ESOP rewards all employees when the shop does well, inspiring many toward continuous improvement as Astro expands its capabilities.

#successionplanning #workforcedevelopment #LargePartMachining

Diving Deeper Into Machine Monitoring Data

By: Julia Hider

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Benchmarking: An Invaluable Business Tool

By: Julia Hider

Modern Machine Shop’s Top Shops program shows shops their strengths and opportunities for improvement, and provides recognition for high-performing businesses.

#topshops

A Higbee Thread Milling Custom Macro

By: Mike Lynch

Higbee threads provide a full thread form at the very start of the thread. The sharp edge is removed during the machining process.

#cnctechtalk